TOOL GAUGE, now renamed DEMGY Pacific, is based in Tacoma, Washington, and brings decades of expertise in precision plastic injection molding and machining of advanced materials for the civil and military aerospace sectors. The company is an award-winning, certified Boeing supplier, having received The Boeing Company’s Silver Performance Excellence Award for nine consecutive years. Its ability to deliver complex, mission-critical components aligns with DEMGY’s commitment to innovation and excellence. With this acquisition, DEMGY significantly strengthens its presence in North America, becomes a Tier 1 supplier to the two largest aircraft manufacturers in the world and a Tier 2 supplier to other aeronautical equipment manufacturers.

"This acquisition reinforces our strategic leadership in high value-added plastics for the aerospace and defense industries, enabling DEMGY Group to become one of the world's leading suppliers of plastic cabin interior parts to Airbus and Boeing, as well as to all American and European aircraft equipment manufacturers,” explains Pierre-Jean LEDUC, Chairman of DEMGY Group. “The recent signing of key agreements with our main customers also enhances our strategic momentum, enabling us to confidently complete the acquisition of TOOL GAUGE under favorable circumstances.”

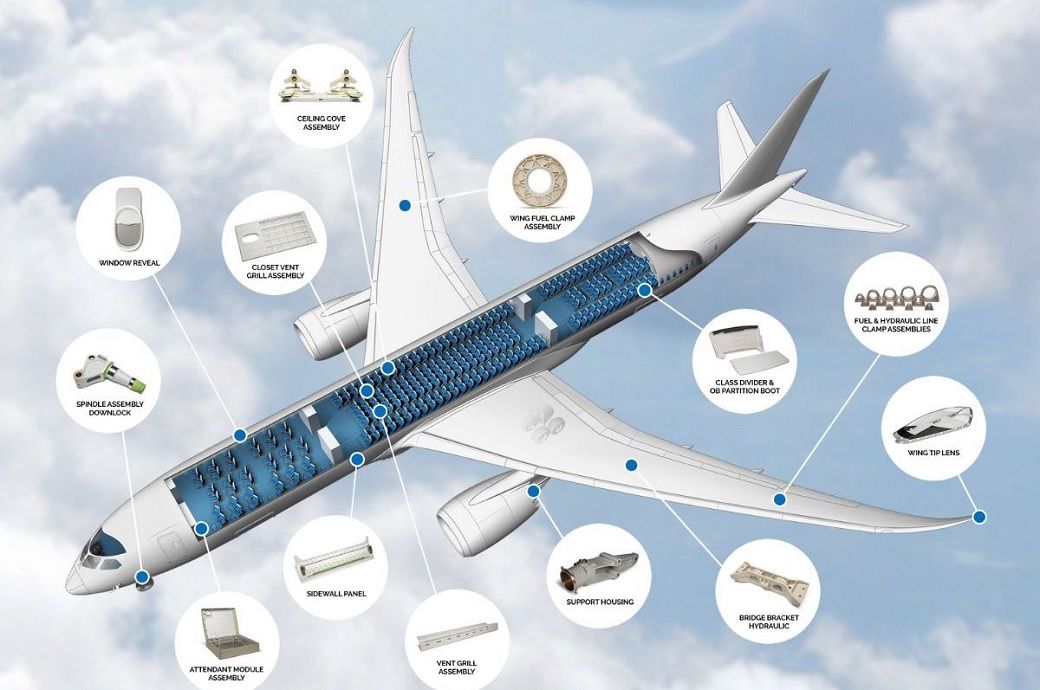

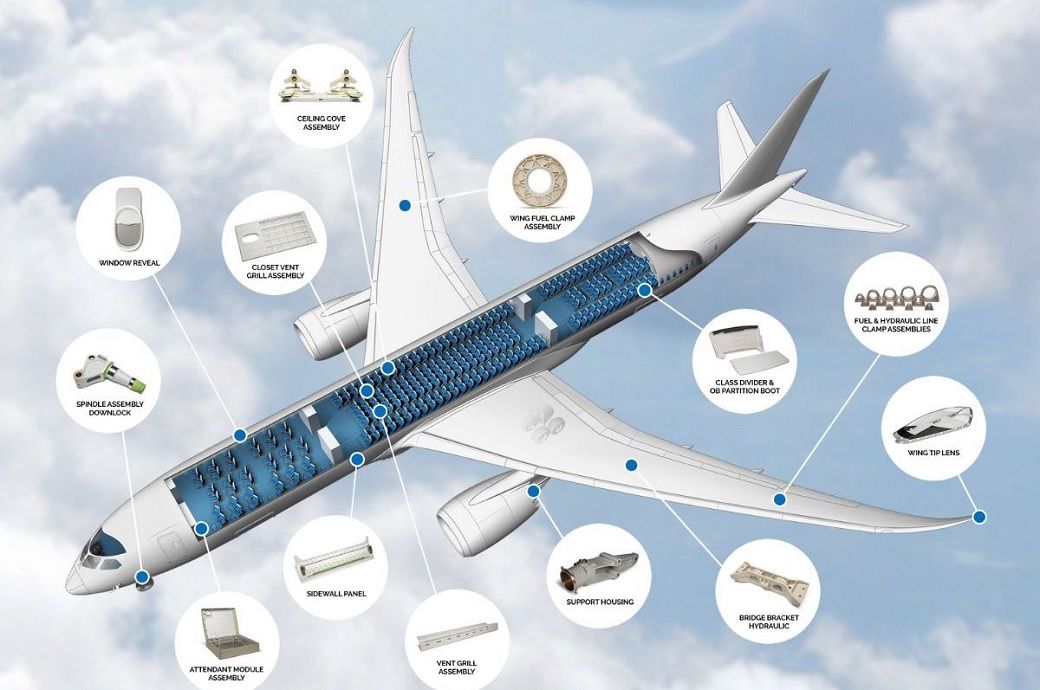

DEMGY Pacific operates two adjacent workshops, one dedicated to injection molding of high-performance polymers and composites for cabin interiors (75% of revenue), and the other focused on precision metal and polymer machining for aerospace spare parts (25%).

This acquisition increases the DEMGY Groups total sites to 10 worldwide (France, Germany, Romania, USA), with 950 employees and projected revenues exceeding €130 million in 2025. The group aims to reach €200 million in annual revenue by 2030.

“We are very excited. TOOL GAUGE is renowned for producing some of the most complex parts in the industry. With their help, DEMGY Group will gain critical know-how and capabilities that will allow us to better serve our global customers and support the industry's push for lighter, more efficient, aircraft through advanced materials and innovation,” concludes Pierre-Jean LEDUC.

Fibre2Fashion News Desk (RM)