Plant Watch Top 10 Engineering Projects of May 2024

Related Vendors

PROCESS Worldwide brings to you the ‘Top 10 plant engineering projects of May 2024’ from all over the world. Right from Carbios holding a groundbreaking ceremony for the world's first pet biorecycling plant to the world’s largest direct air capture plant commencing operations in Iceland, find out all the projects making headlines here.

Domo Chemicals Inaugurates New Polyamide Production Unit

May 02 – Domo Chemicals has inaugurated its newest plant in Haiyan, Jiaxing, Zhejiang, China. This significant milestone reinforces the company’s determination to meet rising demand in the Chinese market for its Technyl polyamide-based intelligent solutions.

The 14-million-euro investment represents a potential doubling of Domo's commitment to the Chinese market, with the new plant capable of increasing the current capacity of 25,000 tons of Technyl polyamides to 35,000 tons and eventually 50,000 tons in the long term. Covering an area of 40,000 square meters, the state-of-the-art facility underscores Domo's unwavering commitment to providing high quality products and services to its customers in key sectors such as automotive, electronics, energy, industrial and consumer goods.

Carbios Holds Groundbreaking Ceremony for World's First Pet Biorecycling Plant

May 06 – Carbios recently celebrated the groundbreaking ceremony for the world's first Pet biorecycling plant in the presence of representatives of local authorities, partner brands and industrial partners who all make up Carbios’ ecosystem. Located in Longlaville, in the Grand-Est region of France, Carbios' first commercial plant will play a key role in the fight against plastic pollution, offering an industrial-scale solution for the enzymatic depolymerization of Pet waste in order to accelerate a circular economy for plastic and textiles. The plant will have a processing capacity of 50kt/year of prepared waste when operating at full capacity. Work is progressing on schedule with significant quantities delivered to customers in 2026.

Pet, the second most widely used plastic in the world, is mainly manufactured from oil. Thanks to Carbios’ enzymatic biorecycling technology, Pet will no longer be made from oil, but from its own waste. This technological breakthrough opens up new recycling streams for multilayered, colored and opaque trays made from packaging waste and polyester textile waste, which until now have been little or not recycled at all, giving them value. In addition, this breakthrough positions France as a pioneer in green innovation, contributing to its reindustrialisation and leadership in the transition to a sustainable economy.

“A technological revolution is taking shape with the groundbreaking ceremony of Carbios’ plant in Longlaville: the world's first biorecycling plant. French pride! Ecological transition and growth, made in France and innovation go hand in hand,” shares Emmanuel Macron, President of France.

World’s Largest Direct Air Capture Plant Begins Operations in Iceland

May 10 – The largest direct air capture and storage plant, named Mammoth, starts operations in Iceland. It is the second commercial facility of Climeworks in Iceland and is about ten times bigger than its predecessor, Orca. Mammoth will bring new high-quality carbon removal capacity to the market for Climeworks to provide to its customers.

Climeworks broke ground on Mammoth in June 2022. The plant is built in a modular design, with twelve of its total 72 collector containers currently installed onsite. The plant will be completed throughout 2024. It is designed for a nameplate capture capacity of up to 36,000 tons of CO₂ per year.

Mammoth has successfully started to capture its first CO₂. Climeworks uses renewable energy to power its direct air capture process, which requires low-temperature heat like boiling water. The geothermal energy partner On Power in Iceland provides the energy necessary for this process. Once the CO₂ is released from the filters, storage partner Carbfix transports the CO₂ underground, where it reacts with basaltic rock through a natural process, which transforms into stone, and remains permanently stored. Climeworks verifies and certifies the whole process by independent third parties.

Carbon Clean Achieves Fabrication Milestone on Europe’s Largest E-Methanol Plant

May 13 – Carbon Clean has achieved a fabrication milestone on Ørsted’s Flagshipone project, Europe’s largest commercial-scale e-methanol facility under construction. The first equipment has been mounted on the structural steel of the first module, marking the start of the module assembly process. Once operational, Carbon Clean’s technology will be capable of capturing 70,000 tonnes of biogenic CO2 per year for Ørsted’s facility in Örnsköldsvik, Sweden.

Carbon Clean’s Capturex semi-modular technology for this project is being fabricated at Schwartz Hautmont’s site at the Port of Tarragona in Vila-seca, Spain. This demonstrates the economic benefits that carbon capture brings to the local supply chain, both in Vila-seca and beyond.

Flagshipone will be Ørsted’s largest commercial-scale Power-to-X facility and Europe’s largest e-methanol plant, and is expected to be operational in 2025. It will supply up to 55,000 tonnes of e-methanol per year to the shipping industry, which today accounts for around 3 % of global carbon emissions.

3M Invests 67-Million-Dollars for Expanding Nebraska Plant

May 15 – A new 90,000-square-foot expansion at 3M's facility in Valley, Nebraska, will increase the plant's manufacturing capacity and add new jobs to the community.

The 67-million-dollar investment includes new production lines, equipment and a warehouse, and will help 3M more quickly meet customer demand for the company's personal safety products. The expansion of the plant is expected to create about 40 new jobs.

The expansion will create additional manufacturing capacity for 3M's reusable respirators and Peltor hearing protection products. To help make the expansion happen, 3M partnered with the state of Nebraska through the Imagine Nebraska Program, a tax incentive-based program intended to encourage companies to invest in Nebraska by creating jobs and growing the state and its economy.

MOL Group Inaugurates 1.3 Billion-Euro Polyol Complex in Hungary

May 16 – MOL's 1.3-billion-euro polyol complex in Tiszaújváros, Hungary boasting a capacity of around 200,000 tonnes of polyol per year, has been inaugurated. The ceremony, addressed by Prime Minister of Hungary Viktor Orbán, MOL's Chairman-CEO, Zsolt Hernádi, and Thyssenkrupp Board member Ilse Henne, marks a significant milestone for the company. MOL Group stands as the sole entity in Hungary and in Central and Eastern Europe to cover the entire value chain, from petroleum processing to polyol production (a widely used plastic raw material).

MOL Group held an inauguration ceremony in Tiszaújváros to celebrate the completion of its largest organic investment, the polyol complex. MOL, Thyssenkrupp and Evonik IP signed the licence agreement in summer 2017, and the foundation stone of the complex was laid in September 2019.

The main units were transported to Tiszaújváros between 2019 and 2020, mainly by water, and were followed by the completion of the complex's hydrogen peroxide, propylene oxide, polyol and propylene glycol plants. In addition to the four main plants, a pilot polyol plant, a quality assurance laboratory and, in Százhalombatta, a Research and Development Center were also built.

JM Technology Chosen for South America’s Largest E-Methanol Plant

May 17 – Johnson Matthey has been selected by HIF Global, the world's leading e-fuels company, as the methanol licensor for HIF Global's Paysandú e-fuels project in Uruguay. The facility would be the largest e-methanol plant in South America and will use electrolytic (green) hydrogen and waste CO2 from an ethanol plant to produce e-methanol. E-methanol, through use of renewable feedstocks, enables the production of a lower carbon fuel versus traditional methanol.

JM's e-methanol emerald technology has been proven as a credible route to decarbonize methanol production and this technology will be deployed at the HIF Paysandú e-fuels facility, with expected production capacity of 700,000 tonnes per year of e-methanol. The e-methanol will be utilized to support the rapidly growing demand from the marine market, as well as a feedstock to produce e-gasoline (via a methanol to gasoline process) which will facilitate the decarbonization of over 150,000 vehicles.

This collaboration builds on the successful demonstration of the emerald technology in the HIF Haru Oni e-fuels facility, where JM licenses its technology and supplies the catalyst. The demo plant has successfully operated for over 12 months, producing methanol that is further processed into gasoline.

HIF Global will invest 4 billion dollars in the facility, making it the most significant investment in Uruguay's history. Construction of the plant is planned for 2025 and is expected to create approximately 1,500 jobs during construction with an additional 300 permanent operational positions.

Astrazeneca to Build 1.5-Billion-Dollar Facility for Antibody Drug Conjugates

May 21 – Astrazeneca intends to build a 1.5-billion-dollar manufacturing facility in Singapore for antibody drug conjugates (ADCs), enhancing global supply of its ADC portfolio. ADCs are next-generation treatments that deliver highly potent cancer-killing agents directly to cancer cells through a targeted antibody.

The planned greenfield facility, supported by the Singapore Economic Development Board (EDB), will be Astrazeneca’s first end-to-end ADC production site, fully incorporating all steps of the manufacturing process at a commercial scale. Manufacturing of ADCs is a multi-step process that comprises antibody production, synthesis of chemotherapy drug and linker, conjugation of drug-linker to the antibody, and filling of the completed ADC substance.

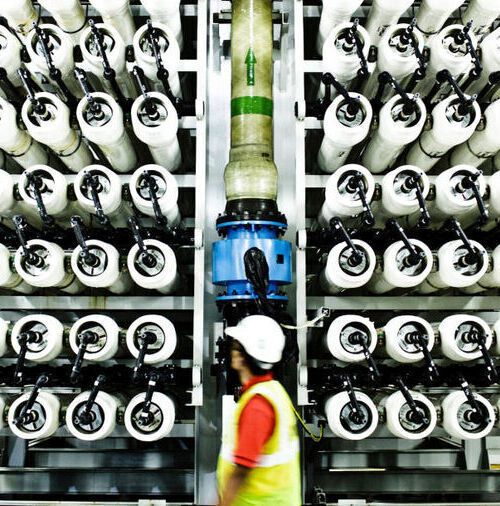

Veolia Wins Contract for World’s Most Energy-Efficient Desalination Plant

May 22 – Veolia through its subsidiary Sidem, will engineer and supply key technology for the Hassyan seawater desalination plant in Dubai, United Arab Emirates (UAE). Commissioned by Dubai Electricity and Water Authority (Dewa) and Acwa Power, the plant will be the second largest desalination plant based on reverse osmosis (RO) technology in the world, and the largest desalination plant powered by solar energy. This significant project underlines Veolia's commitment, reaffirmed in its new Greenup strategic plan, to provide sustainable, low-carbon and energy-efficient solutions, while guaranteeing the preservation of water resources in a context of adaptation to climate change.

Located approximately 55 kilometers southwest of Dubai Creek, the Hassyan desalination plant will have a capacity of 818,000 cubic meters per day (m3/d) — 180 million imperial gallons per day (MIGD) — providing a safe and reliable source of drinking water to two million people. The plant will start operating in 2026, with a gradual ramp-up to full capacity in 2027. The project is part of a broader strategy to sustainably increase water desalination capacity, to help support Dubai's increasing demand for water in domestic and commercial settings. Furthermore, this plant will be the largest desalination plant powered by solar energy in the world.

This project will feature an exceptional energy efficiency performance, with an incredibly low energy consumption rate of 2,9 kilowatt-hours per cubic meter (kWh/m3). Sidem's extensive expertise in large-scale desalination, including the critical pre-treatment and post-treatment stages, has helped maximize the potential of RO technology in terms of energy efficiency, reducing the energy consumption of RO desalination plants by a further 35 % over the past 10 years.

World’s First AI-Based Autonomous Operation of Crude Oil Processing Unit Begins

May 29 – Eneos Corporation (Eneos) and Preferred Networks (PFN) have started continuous autonomous operation of an atmospheric distillation unit for processing crude oil in January 2024. The atmospheric distillation unit currently operated autonomously with an AI system is located in the Eneos Kawasaki Refinery.

Jointly developed by Eneos and PFN, the AI system automates large-scale, complex operations of oil refinery plants that required human operators with years of experience. Since 2018, Eneos and PFN have been co-developing AI systems for improving safety and stability of plant operations by reducing dependence on technicians’ varying skill levels.

With 24 key operational factors to control and as many as 930 sensors to monitor, the atmospheric distillation unit especially requires a high level of skills and experience. AI-based, continuous autonomous operation of an atmospheric distillation unit is the world’s first, according to consulting firm Globe-ing.

The AI system for the atmospheric distillation unit continuously monitors 24 key operational factors and adjusts 13 valves at the same time to stabilize fluctuations resulting from crude oil switching as well as changes in crude oil throughput. The AI system has demonstrated higher stability and efficiency compared with manual operations.

Eneos and PFN plan to deploy the co-developed AI systems to other Eneos refineries and later provide them as a packaged solution to external parties as well. Through this collaboration, Eneos and PFN will also support the United Nations’ Sustainable Development Goals, including Goal 9 (Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation).

(ID:50054068)

:quality(80)/p7i.vogel.de/wcms/f3/a4/f3a4724b3e93ad58d68e83138b14a5c8/0118728087v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/7e/b17ea8c62ccafad1d1fb072d6199bbd6/0118578446.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/3a/cd3a4657041515fb2a44dfc2faa53c7c/0118573632.jpeg)

:quality(80)/p7i.vogel.de/wcms/73/f6/73f6788706994955437d5cd23dae8735/0113343337.jpeg)

:quality(80)/p7i.vogel.de/wcms/61/7a/617a9ddc10943a3cc23b678fdf25b296/0118842062v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1a/01/1a01ba265df34fcbe7d5cbcea47f4934/0118840981v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/f2/39f218d4412852823fe38b927b936a33/0118840535v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/94/6d/946d4f68efc5f1302e18ab26592ce770/0118822057v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9f/7b/9f7b5054d3ac2431293733f1570594a1/0118588762v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/dc/9f/dc9f626d7a46c4a0e2643bc3b2b86e94/0117578075.jpeg)

:quality(80)/p7i.vogel.de/wcms/c3/ad/c3ad79e797e4d8b5f494ea097aa58045/0115572380.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/dc/2fdc39af2c7f5d71b2a34aca488985dc/0115467614.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/56/99564a0d7b94f04575ad85a4769eb656/0118842595v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/74/e6/74e6f0ba31dee007c9a729441dfa3cbd/0118841379v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8c/67/8c67d6e9c68cb9dd46aaa7812774f35a/0118794743v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/27/2f/272fbae4ed2724411a34f8b363c3b06e/0118792686v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/6b/b16b8d35b20bc9e4b199b38efa82757b/0118632588v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/d3/80/d380e21bf5be4326bac04a96fc9bb29a/0118095419.jpeg)

:quality(80)/p7i.vogel.de/wcms/44/91/44910ca3c20dbb62b08f50709e61ce03/0118080308.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/8c/f38cd9194a439768b2c04b08d1848b7f/0117468932.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/a5/cba5cbdfe59d8a9d35c9c62a5ac33aed/0118825841v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/36/9936e620ee327913628910536a6c0df1/0118586650.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/78/8778edf199c3bd9dba5b47fea7c2e0f3/0117540022.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/7b/f87bf30fd24b41505a99a1c32e31490b/0116917218.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/b3/6fb3e3b498371fef63a6270dbc40bfd3/0117539067.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/0a/0f0a177aeb05270d20ea77ecfbc13f3c/0114220617.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/16/f916deed855c8b4ba9eb8588493ac55b/0113158240.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/96/6b966eef012797ff6597b1d1c0c5670f/0112790159.jpeg)

:quality(80)/p7i.vogel.de/wcms/6a/32/6a3203961b318c9429e7c5d19ef594d0/0118822441v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a4/ad/a4add8ae1044942fdbd31fa26ae412cb/0118794848v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/e8/9be8e1eb901550d423d105ee1b47d107/0118791529v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/eb/c9eb583f08e402d9a4f999bdbaaae77c/0118773450v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/29/f8298429c1638b949a6f76346f6709c7/0118701710v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/p7i.vogel.de/wcms/9d/20/9d2008ff789ed6d72289674e88ae8afe/0116655315.jpeg)

:quality(80)/p7i.vogel.de/wcms/e9/94/e9944f12e84de373b767dc8fa5545c1d/0115893933.jpeg)

:quality(80)/p7i.vogel.de/wcms/08/af/08af0b650b9fe0757d6e2a1910b3cbf8/0113641252.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/76/607623faaf746ac27a18e0b564a4c55b/0112691397.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/96/1096071302e340fa3f9942d85f42bc28/0118575320.jpeg)

:quality(80)/p7i.vogel.de/wcms/d9/45/d94521ef61d23d461f8a810ae23361c0/0118558670.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/f9/61f9439b7cbe4/logo-edl.png)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/103000/103097/65.jpg)

:quality(80)/p7i.vogel.de/wcms/0d/71/0d71cddd19646210e8a4b8bfce16792e/0118390298.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/bc/66bcad208452ca8ff663e28e9c6c1c4f/0118296559.jpeg)