Achema Trend Report Global Megatrends in Mechanical Process Engineering

Related Vendors

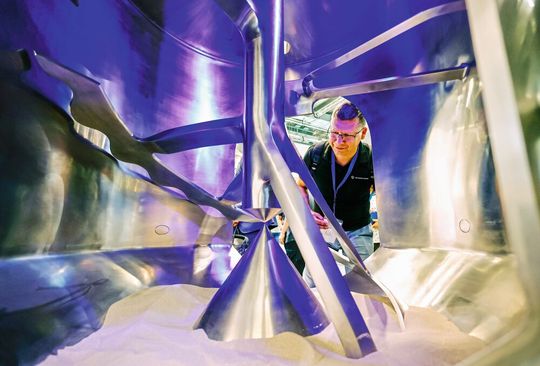

Resource scarcity, mobility, nutrition and climate protection are among the global challenges and megatrends of our time. Mechanical process engineering plays an important role here, because without mixers, separators, extruders, dispersers and the like, many production processes would come to a standstill.

The future belongs to the electrification of the economy and mobility. And energy storage technologies will play a decisive role in this. But if you ask experts where the greatest innovation potential can be expected in battery technology, the answer will surprise most people: not in chemistry and new materials, but in production technology. While a technological optimum is visibly in sight for lithium-ion batteries on the materials side, the production of battery cells and batteries is still far from mature. For example, the energy density, service life and performance of battery cells in general and especially at low temperatures depend crucially on the precision of particle sizes and shaping. And although China is currently the undisputed market leader in the production of batteries for electric cars, this could change in the coming years if new players in the USA and Europe build new battery factories in large numbers using the latest technology.

Researchers from the Fraunhofer Institute for Manufacturing Engineering and Automation, IPA, are convinced that the key to this lies in the production process. Mechanical processes are an important factor: They enable the production and processing of nanomaterials and the precise manufacture of electrodes. The complexity of the battery value chain begins with the extraction of raw materials through mining or chemical extraction — but the process gets really tricky when it comes to processing the materials: these have to be produced not only in consistently high quality (“battery grade”), but also in large quantities. And because active battery materials are toxic, the production processes must also be hermetically sealed (containment).

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/cd/3a/cd3a4657041515fb2a44dfc2faa53c7c/0118573632.jpeg)

:quality(80)/p7i.vogel.de/wcms/73/f6/73f6788706994955437d5cd23dae8735/0113343337.jpeg)

:quality(80)/p7i.vogel.de/wcms/31/73/3173f96e843489f815d1624ac6b2d790/0118442595.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/12/69124b7b6a29588e197274e768f3a3c0/0118202141.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/06/6b068cf6cef22a59b97fea61d82f5c41/0118585386.jpeg)

:quality(80)/p7i.vogel.de/wcms/e3/80/e3804285d940518ef863ac4ab8748f0e/0118553224.jpeg)

:quality(80)/p7i.vogel.de/wcms/dc/e3/dce314c6e3c86431902b5a3687fdb1de/0118546270.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/9f/699f48127f09b1b98c07f5335ae0ac26/0118503355.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/d0/a8d0dd0e4ddecf552892e2fa30a0693b/0115332124.jpeg)

:quality(80)/p7i.vogel.de/wcms/dc/9f/dc9f626d7a46c4a0e2643bc3b2b86e94/0117578075.jpeg)

:quality(80)/p7i.vogel.de/wcms/c3/ad/c3ad79e797e4d8b5f494ea097aa58045/0115572380.jpeg)

:quality(80)/p7i.vogel.de/wcms/2f/dc/2fdc39af2c7f5d71b2a34aca488985dc/0115467614.jpeg)

:quality(80)/p7i.vogel.de/wcms/d9/45/d94521ef61d23d461f8a810ae23361c0/0118558670.jpeg)

:quality(80)/p7i.vogel.de/wcms/2d/7a/2d7a90dece256c495d628099697be468/0118557472.jpeg)

:quality(80)/p7i.vogel.de/wcms/ac/dc/acdcf665b6381c0465752af80964cae5/0118579480.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/03/0f030033015b7b5de8ccb6231dd5ffe4/0118546748.jpeg)

:quality(80)/p7i.vogel.de/wcms/d3/80/d380e21bf5be4326bac04a96fc9bb29a/0118095419.jpeg)

:quality(80)/p7i.vogel.de/wcms/44/91/44910ca3c20dbb62b08f50709e61ce03/0118080308.jpeg)

:quality(80)/p7i.vogel.de/wcms/f3/8c/f38cd9194a439768b2c04b08d1848b7f/0117468932.jpeg)

:quality(80)/p7i.vogel.de/wcms/61/dd/61ddc7c9dde89728d232924a26412426/0116427128.jpeg)

:quality(80)/p7i.vogel.de/wcms/99/36/9936e620ee327913628910536a6c0df1/0118586650.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/78/8778edf199c3bd9dba5b47fea7c2e0f3/0117540022.jpeg)

:quality(80)/p7i.vogel.de/wcms/f8/7b/f87bf30fd24b41505a99a1c32e31490b/0116917218.jpeg)

:quality(80)/p7i.vogel.de/wcms/62/5c/625c02552d8b898439c872b0380aed64/0116814156.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/b3/6fb3e3b498371fef63a6270dbc40bfd3/0117539067.jpeg)

:quality(80)/p7i.vogel.de/wcms/0f/0a/0f0a177aeb05270d20ea77ecfbc13f3c/0114220617.jpeg)

:quality(80)/p7i.vogel.de/wcms/f9/16/f916deed855c8b4ba9eb8588493ac55b/0113158240.jpeg)

:quality(80)/p7i.vogel.de/wcms/6b/96/6b966eef012797ff6597b1d1c0c5670f/0112790159.jpeg)

:quality(80)/p7i.vogel.de/wcms/9a/96/9a96fe19271c235705663c8a53cd99fc/0118585779.jpeg)

:quality(80)/p7i.vogel.de/wcms/10/96/1096071302e340fa3f9942d85f42bc28/0118575320.jpeg)

:quality(80)/p7i.vogel.de/wcms/62/fa/62facd06cdef33a983458f3747e6cc8f/0118558342.jpeg)

:quality(80)/p7i.vogel.de/wcms/79/61/7961ff45d3b7d59b405021dfedddf454/0118286595.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/24/07242664ab2b1c7841c9d9d0a127670c/0116045959.jpeg)

:quality(80)/p7i.vogel.de/wcms/c9/79/c979a20b32395ddfa93fe7ead90578a0/0108386061.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/5c/9e5c92d942ed046a27562d6e3d730c92/0103483548.jpeg)

:quality(80)/images.vogel.de/vogelonline/bdb/1952700/1952707/original.jpg)

:quality(80)/p7i.vogel.de/wcms/9d/20/9d2008ff789ed6d72289674e88ae8afe/0116655315.jpeg)

:quality(80)/p7i.vogel.de/wcms/e9/94/e9944f12e84de373b767dc8fa5545c1d/0115893933.jpeg)

:quality(80)/p7i.vogel.de/wcms/08/af/08af0b650b9fe0757d6e2a1910b3cbf8/0113641252.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/76/607623faaf746ac27a18e0b564a4c55b/0112691397.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/b2/0ab22461ba40a93b798dad2283752c52/0118558308.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/2000/2093/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/61/f9/61f9439b7cbe4/logo-edl.png)

:fill(fff,0)/p7i.vogel.de/companies/5f/98/5f98fbb2e7bf2/05-trm-filter-logo-with-slogan-en-alt.png)

:quality(80)/p7i.vogel.de/wcms/4b/35/4b356d75179f93878f93477b484102a8/0117817451.jpeg)

:quality(80)/p7i.vogel.de/wcms/c4/91/c491054bc13357314b46f6acfaa9a1bc/0117858499.jpeg)