- News

- City News

- coimbatore News

- This workshop ensures no 'signal interference'

This workshop ensures no 'signal interference'

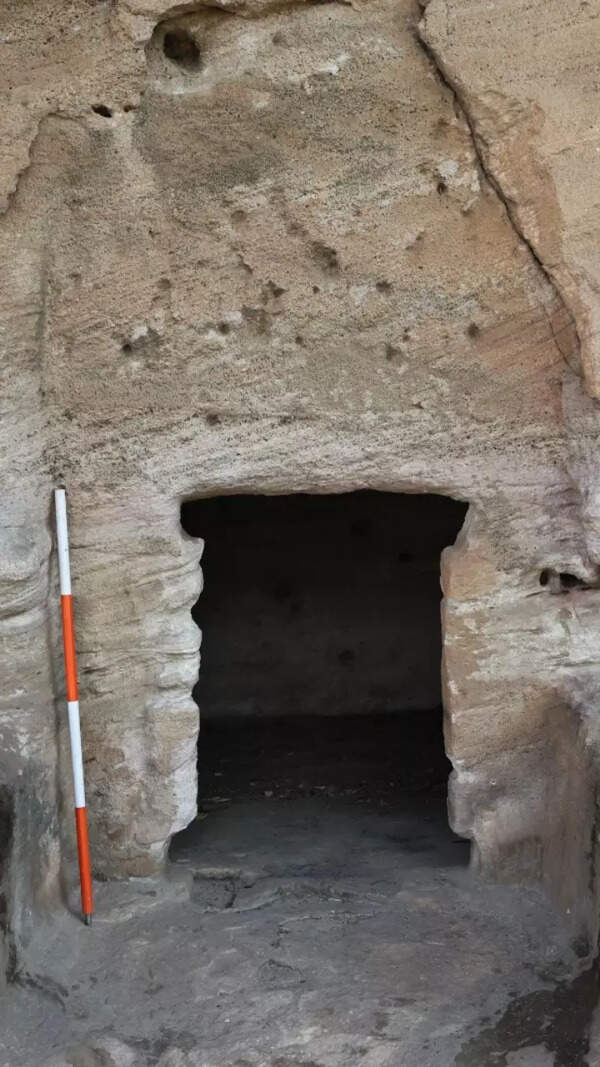

Rows of point machines, a vital device for railway signalling, lay properly arranged on the floor of the building, while signal relay equipment are kept ready for assembling at another place. In the next month or so, the equipment will be shipped to every nook and corner of the country, where they will find a place along the tracks on the vast network of the India Railways.

The building, Signal and Telecommunication (S&T) Workshop of the India Railways at Podanur in Coimbatore, has been a key player in the domain of railway safety, manufacturing crucial signal and telecommunication equipment for the past six-and-a-half-decade.

After a slump in production during Covid, the workshop planned to diversify, adding a lot more equipment to its menu, even as it ramped up production from its existing list.

“For better railway safety, we plan to manufacture advanced safety equipment,” said P Radha Krishnan, chief office superintendent of the workshop.

"By facilitating transfer of technology (TOT), we can make the products within our unit," the superintendent said.

The workshop came into focus after the recent Odisha train accident that killed more than 250 people due to 'signalling interference'.

The workshop was initially started as a repair shop in 1958 for mechanical signalling items at Golden Rock Workshop in Trichy. It was shifted to Podanur the same year with a staff strength of 60. It now operates with a manpower of 735 staff members.

“While there are nine other signal and telecommunication workshops run by the Indian Railways, ours is a major unit,” Radha Krishnan said.

Among the equipment that the workshop manufactures are electric point machines (EPM), which are installed in railway stations, enabling trains to change from one track to another, said senior section engineer R Sridhar.

According to official numbers, the workshop manufactured and supplied more than 70,000 EPMs to the Indian Railways in the last two decades.

General railway signal apparatus case is another equipment to house signalling equipment near the track. The workshop also manufactures electric lifting barrier gates (electrically operated device for closing the level crossing against road traffic) and tokenless block instrument (ensures safety of running trains in a single track and the controlling signals will only allow one train at a time into the track from either end of the station).

The workshop was on the growth path till 2019 – 20, when the pandemic brought down the turnover from Rs 106.5 crore to Rs. 81.66 crore in 2020-21. However, it is slowly recovering and registering a gradual increase in turnover, which increased by Rs 9 crore in 2021 – 22 and a further rise by 3.5 crore in 2022-23.

This year, the officials have set an ambitious target of doubling the turnover. “We have a target to almost double the turnover to around Rs. 177 crore by ramping up production of the existing products,” Radhakrishnan added.

The building, Signal and Telecommunication (S&T) Workshop of the India Railways at Podanur in Coimbatore, has been a key player in the domain of railway safety, manufacturing crucial signal and telecommunication equipment for the past six-and-a-half-decade.

After a slump in production during Covid, the workshop planned to diversify, adding a lot more equipment to its menu, even as it ramped up production from its existing list.

“For better railway safety, we plan to manufacture advanced safety equipment,” said P Radha Krishnan, chief office superintendent of the workshop.

Though the workshop has not finalised the list of new equipment, the plan includes manufacture of remote diagnostic and predictive maintenance system, power supply for virtual display units and telecom integrated power supply system. These are advanced equipment which play important role in rail safety. All these years, the railway’s outsourced manufacture of these equipment.

"By facilitating transfer of technology (TOT), we can make the products within our unit," the superintendent said.

The workshop came into focus after the recent Odisha train accident that killed more than 250 people due to 'signalling interference'.

The workshop was initially started as a repair shop in 1958 for mechanical signalling items at Golden Rock Workshop in Trichy. It was shifted to Podanur the same year with a staff strength of 60. It now operates with a manpower of 735 staff members.

“While there are nine other signal and telecommunication workshops run by the Indian Railways, ours is a major unit,” Radha Krishnan said.

Among the equipment that the workshop manufactures are electric point machines (EPM), which are installed in railway stations, enabling trains to change from one track to another, said senior section engineer R Sridhar.

According to official numbers, the workshop manufactured and supplied more than 70,000 EPMs to the Indian Railways in the last two decades.

General railway signal apparatus case is another equipment to house signalling equipment near the track. The workshop also manufactures electric lifting barrier gates (electrically operated device for closing the level crossing against road traffic) and tokenless block instrument (ensures safety of running trains in a single track and the controlling signals will only allow one train at a time into the track from either end of the station).

The workshop was on the growth path till 2019 – 20, when the pandemic brought down the turnover from Rs 106.5 crore to Rs. 81.66 crore in 2020-21. However, it is slowly recovering and registering a gradual increase in turnover, which increased by Rs 9 crore in 2021 – 22 and a further rise by 3.5 crore in 2022-23.

This year, the officials have set an ambitious target of doubling the turnover. “We have a target to almost double the turnover to around Rs. 177 crore by ramping up production of the existing products,” Radhakrishnan added.

Start a Conversation

FOLLOW US ON SOCIAL MEDIA

FacebookTwitterInstagramKOO APPYOUTUBE