Trending Topics

End of India's dependence on Chinese lithium? How new lithium reserves can boost Electric Vehicle adoption

The latest discovery of large lithium reserves in Rajasthan’s Degana is big news because combined with the estimated 5.9 million tonnes of lithium found in Jammu and Kashmir, the new found resources have the potential to change India’s trajectory towards becoming an energy independent nation. India, the third-largest oil importer in the world, currently procures 80% of its oil needs from other countries, which puts a significant strain on the nation’s foreign exchange reserves. By developing its lithium reserves, India can reduce its dependence on imported oil and save billions of dollars in foreign exchange. It isn’t just oil where India loses forex but India is completely dependent on foreign imports for its lithium needs, which is mainly imported from China. Considering how our political relations with China are, it wouldn't take long to understand why this strategy of importing crucial resources from China isn't a good one.

However, the discovery of the lithium reserves and emergence of EV adoption could change it all as it can protect India from rapidly increasing global prices of lithium, cut down expenditure on oil imports, reduce dependence on China and create jobs and economic growth in the country. The mining and processing of lithium requires specialised skills and technology, which could be developed indigenously although it isn't a process that can be developed overnight. However, if done right, this would create new job opportunities for skilled workers and boost the country's manufacturing sector. In addition, the development of lithium reserves will most likely attract foreign investments and technology transfer, which will further boost economic growth.

Development will take place in downstream industries such as battery manufacturing as well. Pankaj Sharma, Co-Founder and Director, Log9 Materials, which recently opened India’s first indigenous lithium-ion cell manufacturing facility in Bengaluru, said, “With the lithium reserves found in Rajasthan, our resolve for energy independence can only get stronger. Should most of the Lithium reserves discovered be extracted and be capable of being processed to lithium carbonate and derivatives, India will be in a position to not just cater to its own Li-ion battery needs, but will also hold a dominant position as a critical supplier of the element globally.”

Sharma further stated that development of the reserves is particularly important to the regions where they are located, as it can lead to the development of ancillary industries and infrastructure, such as mining equipment manufacturing, processing plants, and logistics. Growth of the domestic battery manufacturing has obvious benefits for the country’s economy and the availability of domestic lithium will enable India to develop a more sustainable and resilient supply chain for critical minerals. This can enhance the country's strategic autonomy and reduce its vulnerability to supply chain disruptions.

Finally, the development of lithium reserves in India would help the country achieve its net-zero climate goals. India is one of the largest emitters of greenhouse gases in the world, and reducing its carbon footprint is a key priority for the country. According to Nitin Kapoor, Managing Director of Saera Electric Auto Private Limited, “The availability of lithium from domestic reserves supports the government's ambitious target of achieving 30% electric mobility by 2030, and will help in mitigating climate change by reducing emissions. It can accelerate the shift towards sustainable and cleaner transportation, boost the domestic manufacturing sector, and contribute to the government's vision of a greener future.”

The use of lithium-ion batteries in electric vehicles is expected to grow significantly in the coming years. According to a report by Bloomberg New Energy Finance, electric vehicles could account for nearly 30% of new car sales worldwide by 2040. India also is pursuing an aggressive EV adoption plan and the development of lithium reserves in Jammu and Kashmir and Rajasthan would provide a significant boost to India's EV industry. It would help reduce the cost of electric vehicles and make them more affordable for consumers among many other benefits.

According to a study conducted by the Council on Energy, Environment and Water (CEEW), the cumulative energy storage requirement from utility storage and electric vehicles is expected to be 903 GWh between 2021 to 2030. Considering that its costs USD 4.5 billion to set up a 50 GWh lithium-ion cell and battery manufacturing plant, under the Production Linked Incentive (PLI) scheme, the new found reserves could help bring down these costs significantly and catapult India into becoming a major stakeholder in the global lithium supply chain.

Moreover, the high content of lithium found in the Jammu and Kashmir reserves, will give India an added edge as our yield will be higher than other countries. According to the Geological Survey of India (GSI), the standard lithium found elsewhere is 220 parts per million (ppm), while in Jammu and Kashmir, the lithium found is estimated to be at 500 ppm density. This means we yield twice the lithium for the same effort.

Combined with the fact that lithium can be recycled and reused indefinitely, this puts India in a prime position to benefit in a circular manner. Mining, processing, manufacturing and recycling can be done under the same ‘roof’ so to say and domestic stakeholders get to control the supply chain. Over time, when India starts producing 10 million EVs annually, the same amount of used EV battery packs will start getting recycled, this means the EV battery packs will become neutral as they are built out of recycled lithium.

In a recent conversation with TOI Auto, Rajat Verma, Founder & CEO, Lohum, said “In 2022, the global ecosystem manufactured about 800 GWH of batteries. We expect this number to go up to 3,000 GWH by 2027-28. Now that is the amount of material that will come back by 2034-35 once the batteries reach end-of-life. Can we have a vision that 50 percent of that material actually comes to India and we recycle it and start controlling the global supply chain. That is the vision we should have. That means that we should be talking about creating 1,500 to 2,000 GWH of battery recycling capacity in this country. Today, we don’t even have 5 GWH of recycling capacity.”

Riding on a race track no longer costs a bomb | TOI Auto

However, the discovery of the lithium reserves and emergence of EV adoption could change it all as it can protect India from rapidly increasing global prices of lithium, cut down expenditure on oil imports, reduce dependence on China and create jobs and economic growth in the country. The mining and processing of lithium requires specialised skills and technology, which could be developed indigenously although it isn't a process that can be developed overnight. However, if done right, this would create new job opportunities for skilled workers and boost the country's manufacturing sector. In addition, the development of lithium reserves will most likely attract foreign investments and technology transfer, which will further boost economic growth.

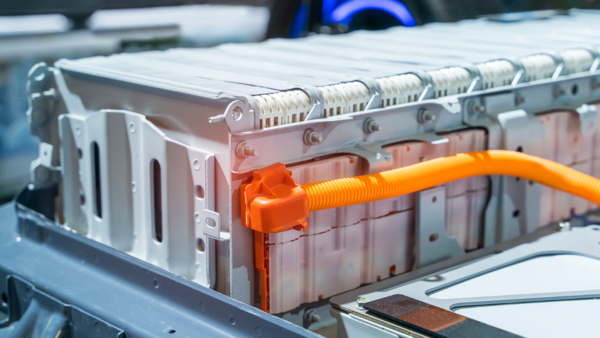

Representational image

Development will take place in downstream industries such as battery manufacturing as well. Pankaj Sharma, Co-Founder and Director, Log9 Materials, which recently opened India’s first indigenous lithium-ion cell manufacturing facility in Bengaluru, said, “With the lithium reserves found in Rajasthan, our resolve for energy independence can only get stronger. Should most of the Lithium reserves discovered be extracted and be capable of being processed to lithium carbonate and derivatives, India will be in a position to not just cater to its own Li-ion battery needs, but will also hold a dominant position as a critical supplier of the element globally.”

Sharma further stated that development of the reserves is particularly important to the regions where they are located, as it can lead to the development of ancillary industries and infrastructure, such as mining equipment manufacturing, processing plants, and logistics. Growth of the domestic battery manufacturing has obvious benefits for the country’s economy and the availability of domestic lithium will enable India to develop a more sustainable and resilient supply chain for critical minerals. This can enhance the country's strategic autonomy and reduce its vulnerability to supply chain disruptions.

Representational image

Finally, the development of lithium reserves in India would help the country achieve its net-zero climate goals. India is one of the largest emitters of greenhouse gases in the world, and reducing its carbon footprint is a key priority for the country. According to Nitin Kapoor, Managing Director of Saera Electric Auto Private Limited, “The availability of lithium from domestic reserves supports the government's ambitious target of achieving 30% electric mobility by 2030, and will help in mitigating climate change by reducing emissions. It can accelerate the shift towards sustainable and cleaner transportation, boost the domestic manufacturing sector, and contribute to the government's vision of a greener future.”

The use of lithium-ion batteries in electric vehicles is expected to grow significantly in the coming years. According to a report by Bloomberg New Energy Finance, electric vehicles could account for nearly 30% of new car sales worldwide by 2040. India also is pursuing an aggressive EV adoption plan and the development of lithium reserves in Jammu and Kashmir and Rajasthan would provide a significant boost to India's EV industry. It would help reduce the cost of electric vehicles and make them more affordable for consumers among many other benefits.

Representational image

According to a study conducted by the Council on Energy, Environment and Water (CEEW), the cumulative energy storage requirement from utility storage and electric vehicles is expected to be 903 GWh between 2021 to 2030. Considering that its costs USD 4.5 billion to set up a 50 GWh lithium-ion cell and battery manufacturing plant, under the Production Linked Incentive (PLI) scheme, the new found reserves could help bring down these costs significantly and catapult India into becoming a major stakeholder in the global lithium supply chain.

Moreover, the high content of lithium found in the Jammu and Kashmir reserves, will give India an added edge as our yield will be higher than other countries. According to the Geological Survey of India (GSI), the standard lithium found elsewhere is 220 parts per million (ppm), while in Jammu and Kashmir, the lithium found is estimated to be at 500 ppm density. This means we yield twice the lithium for the same effort.

Representational image

Combined with the fact that lithium can be recycled and reused indefinitely, this puts India in a prime position to benefit in a circular manner. Mining, processing, manufacturing and recycling can be done under the same ‘roof’ so to say and domestic stakeholders get to control the supply chain. Over time, when India starts producing 10 million EVs annually, the same amount of used EV battery packs will start getting recycled, this means the EV battery packs will become neutral as they are built out of recycled lithium.

In a recent conversation with TOI Auto, Rajat Verma, Founder & CEO, Lohum, said “In 2022, the global ecosystem manufactured about 800 GWH of batteries. We expect this number to go up to 3,000 GWH by 2027-28. Now that is the amount of material that will come back by 2034-35 once the batteries reach end-of-life. Can we have a vision that 50 percent of that material actually comes to India and we recycle it and start controlling the global supply chain. That is the vision we should have. That means that we should be talking about creating 1,500 to 2,000 GWH of battery recycling capacity in this country. Today, we don’t even have 5 GWH of recycling capacity.”

About the Author

Amber BanerjeeAmber is a keen automotive enthusiast, with an extensive background in producing both video and editorial content.

Start a Conversation

FOLLOW US ON SOCIAL MEDIA

FacebookTwitterInstagramKOO APPYOUTUBE