Top Searches

- News

- City News

- varanasi News

- Built in 1892, water treatment plant supplying pure water in old kashi

Built in 1892, water treatment plant supplying pure water in old kashi

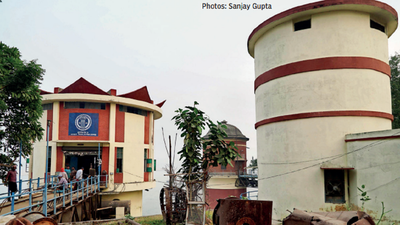

The water treatment plant (WTP) at Bhelupur

VARANASI: “ Ab pani ke rang saaf ho gayal hao, aur ab dawai wali mahak bhi nahi awat (the water has now become clear and doesn’t smell like medicines),” said tea-seller Ajit Kumar Yadav, while fetching water from a public tap outside his kiosk in Sonia area.

Like Yadav, people in the old city areas of Kashi have started experiencing a pleasant change in the quality of water supplied from the water treatment plant (WTP) built in 1892 in Kamaksha Bhelupur area after getting raw ‘Gangajal’ from the water lifting pump at Bhadaini on the bank of the river Ganga.

Run by Jal Kal, this WTP is supplying potable water in sis-Varuna area of the city since 130 years. But, the change in the quality of water is being felt with the replacement of poly aluminium chloride (PAC) — earlier used for coagulation and flocculation of raw water treatment — by the polymer dosing plant.

“We introduced polymer dosing plant and started supply for testing in August. Since September, we have started supplying water treated from this plant in the area under coverage of Bhelupur WTP. Regular monitoring of water quality in the past three months has showed consistency in supply of improved quality of potable water with minerals and natural qualities of Gangajal,” said Jal Kal general manager Raghuvendra Kumar, mentioning that the water is clear like bottled water and also free of demerits of PAC.

“Among the cities along the river Ganga, Kashi has become the first to introduce this technology,” said Jal Kal secretary Siddharth Kumar.

Claims of Jal Kal officials were justified by the consumers in old city areas. A homemaker in Awadhgarvi, Shalu Modanwal, said: “When we fill water in bottles to put in the refrigerator, we notice that it is clearer like bottled water sold in markets. This change is evident for the past three months.

” An academician in Sonarpura, Alka R Gupta, said: “Im- provement is the quality has been felt as longevity of cleaning filters of water purifiers has gone up.” Another academician, Dr Seema Mishra, of Kirahiya Khojwa locality said that better purification of water is evident everyday. A street vendor in Chandua Chittupur, Kamlesh Gupta, said: “Earlier, we used to collect unclear water with foul smell in our locality. But, for the past three months we are getting clear water without any foul smell.”

Regarding WTP operation, the Jal Kal officials informed TOI: “Altogether, 120 MLD raw water was lifted from river Ganga at Bhadaini and supplied to WTP Bhelupur for treatment and making it potable following coagulation, sedimentation, filtration and disinfection. Traditionally, PAC was used widely for coagulation and flocculation of raw water treatment at this WTP.

” To minimize the use of PAC due to its demerits and improve the water quality, officials said, Jal Kal Varanasi introduced polymer dosing plant. Incidentally, organic polymer dosing is a cutting edge technology for surface water treatment and is available in European and developed western countries. Use of INDFLOC 238 polymer chemical as coagulant and INDFLOC 27 high efficiency polyelectrolyte, specially designed for solid liquid separation process as flocculant, was started, they explained. Both products are certified by the National Sanitation Foundation and Indian Institute of Toxicology (Pune & Lucknow).

The objective of addition of flocculent (polymer food grade) is to replace alum and also to reduce the consumption of the conventional chemicals like PAC for faster settling of suspended impurities, better clarity, less turbidity of the potable drinking water and reduction in the quantity of sludge. Highlighting the advantages of the newly inducted technology, they mentioned that water treated with aluminium salts contain forms of soluble aluminium, which is a prevalent bioavailable source ingested by humans. Residual aluminium in treated water is undesirable for aesthetic reasons, but also because of a possible link between aluminium and adverse neurological effects such as Alzheimer’s disease.

“In order to reduce its presence in drinking water, the use of alternative treatment process was adopted, although 100% replacement of metal coagulant in drinking water application is not possible because of cost implications,” mentioned Jal Kal officials, adding, “With our treatment program doses of PAC can be reduced almost 5-10 times, which will result in less sludge generation, along with desired water quality.” The Jal Kal tests water quality in its own laboratory four times in a day, the officials said adding, the feedback from people in coverage area of WTP is also being taken regularly

Currently, Jal Kal is treating 120 MLD water per day to meet the requirement of around 10 lakh population in sis-Varuna areas of old Kashi. Siddhant Kumar said: “To maintain pressure of water supplied from Bhelupur WTP in far areas around 118 tubewell are also being operated by linking them with main lines and meet the total requirement of 240 MLD water in sis-Varuna. The capacity of WTP and polymer dosing plant would be increased to treat up to 250 MLD water per day. Once the capacity will be augmented the tubewells would become standby.”

“Jal Kal has switched to polymer dosing plant technology without any onetime major investment,” said Siddharth Kumar and added that as per the tie-up with companies, they would be paid only the cost of chemicals supplied to Jal Kal to operate the plant. This cost would be arranged by Jal Kal with its own resources, he further said.

Like Yadav, people in the old city areas of Kashi have started experiencing a pleasant change in the quality of water supplied from the water treatment plant (WTP) built in 1892 in Kamaksha Bhelupur area after getting raw ‘Gangajal’ from the water lifting pump at Bhadaini on the bank of the river Ganga.

Run by Jal Kal, this WTP is supplying potable water in sis-Varuna area of the city since 130 years. But, the change in the quality of water is being felt with the replacement of poly aluminium chloride (PAC) — earlier used for coagulation and flocculation of raw water treatment — by the polymer dosing plant.

“We introduced polymer dosing plant and started supply for testing in August. Since September, we have started supplying water treated from this plant in the area under coverage of Bhelupur WTP. Regular monitoring of water quality in the past three months has showed consistency in supply of improved quality of potable water with minerals and natural qualities of Gangajal,” said Jal Kal general manager Raghuvendra Kumar, mentioning that the water is clear like bottled water and also free of demerits of PAC.

“Among the cities along the river Ganga, Kashi has become the first to introduce this technology,” said Jal Kal secretary Siddharth Kumar.

Claims of Jal Kal officials were justified by the consumers in old city areas. A homemaker in Awadhgarvi, Shalu Modanwal, said: “When we fill water in bottles to put in the refrigerator, we notice that it is clearer like bottled water sold in markets. This change is evident for the past three months.

” An academician in Sonarpura, Alka R Gupta, said: “Im- provement is the quality has been felt as longevity of cleaning filters of water purifiers has gone up.” Another academician, Dr Seema Mishra, of Kirahiya Khojwa locality said that better purification of water is evident everyday. A street vendor in Chandua Chittupur, Kamlesh Gupta, said: “Earlier, we used to collect unclear water with foul smell in our locality. But, for the past three months we are getting clear water without any foul smell.”

Regarding WTP operation, the Jal Kal officials informed TOI: “Altogether, 120 MLD raw water was lifted from river Ganga at Bhadaini and supplied to WTP Bhelupur for treatment and making it potable following coagulation, sedimentation, filtration and disinfection. Traditionally, PAC was used widely for coagulation and flocculation of raw water treatment at this WTP.

” To minimize the use of PAC due to its demerits and improve the water quality, officials said, Jal Kal Varanasi introduced polymer dosing plant. Incidentally, organic polymer dosing is a cutting edge technology for surface water treatment and is available in European and developed western countries. Use of INDFLOC 238 polymer chemical as coagulant and INDFLOC 27 high efficiency polyelectrolyte, specially designed for solid liquid separation process as flocculant, was started, they explained. Both products are certified by the National Sanitation Foundation and Indian Institute of Toxicology (Pune & Lucknow).

The objective of addition of flocculent (polymer food grade) is to replace alum and also to reduce the consumption of the conventional chemicals like PAC for faster settling of suspended impurities, better clarity, less turbidity of the potable drinking water and reduction in the quantity of sludge. Highlighting the advantages of the newly inducted technology, they mentioned that water treated with aluminium salts contain forms of soluble aluminium, which is a prevalent bioavailable source ingested by humans. Residual aluminium in treated water is undesirable for aesthetic reasons, but also because of a possible link between aluminium and adverse neurological effects such as Alzheimer’s disease.

“In order to reduce its presence in drinking water, the use of alternative treatment process was adopted, although 100% replacement of metal coagulant in drinking water application is not possible because of cost implications,” mentioned Jal Kal officials, adding, “With our treatment program doses of PAC can be reduced almost 5-10 times, which will result in less sludge generation, along with desired water quality.” The Jal Kal tests water quality in its own laboratory four times in a day, the officials said adding, the feedback from people in coverage area of WTP is also being taken regularly

Currently, Jal Kal is treating 120 MLD water per day to meet the requirement of around 10 lakh population in sis-Varuna areas of old Kashi. Siddhant Kumar said: “To maintain pressure of water supplied from Bhelupur WTP in far areas around 118 tubewell are also being operated by linking them with main lines and meet the total requirement of 240 MLD water in sis-Varuna. The capacity of WTP and polymer dosing plant would be increased to treat up to 250 MLD water per day. Once the capacity will be augmented the tubewells would become standby.”

“Jal Kal has switched to polymer dosing plant technology without any onetime major investment,” said Siddharth Kumar and added that as per the tie-up with companies, they would be paid only the cost of chemicals supplied to Jal Kal to operate the plant. This cost would be arranged by Jal Kal with its own resources, he further said.

FOLLOW US ON SOCIAL MEDIA

FacebookTwitterInstagramKOO APPYOUTUBE

Start a Conversation

end of article