Shallow water, marshy water bed, tidal waves, and the fact that the bridge is being built between two existing bridges makes the project an extremely difficult and challenging one. (Amit Chakravarty)

Shallow water, marshy water bed, tidal waves, and the fact that the bridge is being built between two existing bridges makes the project an extremely difficult and challenging one. (Amit Chakravarty) IN 1959, the S G Barve-headed Study Group for Greater Bombay suggested the construction of a rail-cum-road bridge over the Thane Creek, which, it felt, would open up new areas for industrial development and absorption of the increasing population of Greater Bombay. Fourteen years after the suggestion was first made, a two-lane bridge with an aim to provide an east-west axis between Mumbai and Navi Mumbai was constructed in 1973.

This bridge laid the grounds for the emergence of Navi Mumbai as a counter magnet to Mumbai city. Five decades down the line, the Maharashtra government is planning to construct a third bridge over the Thane Creek to provide connectivity to Navi Mumbai and beyond.

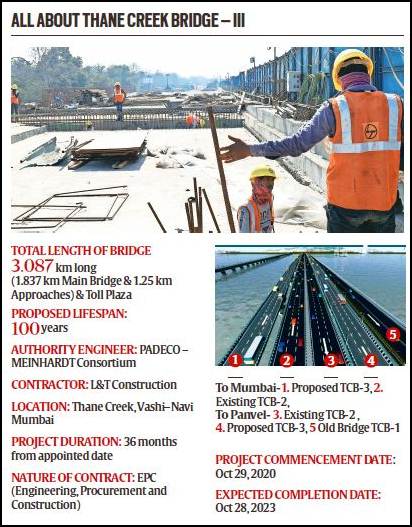

Compared to 21.8-km-long Mumbai Trans-Harbour Link sea bridge, the 1.8-km-long bridge being built over the Thane Creek to connect Mumbai with Navi Mumbai between Mankhurd and Vashi looks relatively small. However, shallow water, marshy water bed, tidal waves, and the fact that the bridge is being built between two existing bridges make the project an extremely difficult and challenging one for the 600+plus workers and engineers who are working overtime to complete it before October 2023.

THE THANE CREEK AND ITS BRIDGES

The Thane Creek Bridge 3, or TCB-3 as it is known, comprises two separate three-laned bridges, each 1.8 kilometers in length, being built across Thane Creek channel connecting Mumbai and Navi Mumbai by the Maharashtra State Road Development Corporation (MSRDC).

This is an expansion of the existing two bridges called as TCB1 and TCB2 to provide seamless travel to motorists between the two cities.

The first two-lane bridge over the Thane Creek bridge was built in 1973 to connect the city and Navi Mumbai and was named as Thane Creek Bridge-1. This bridge, however, fell into disrepair within a few years forcing the state to construct Thane Creek Bridge 2 (TCB-2) — two separate two-laned bridges — in 1987, opened to public in 1997.

By 2010-2011, owing to massive urbanisation in Navi Mumbai, the movement of commuters between the two cities started increasing, rendering the existing bridges inadequate.

According to officials, motorists have access to nearly 10 lanes of road when they drive from Mumbai or Navi Mumbai

towards the Thane Creek Bridge. The TCB, however, creates a massive bottleneck as it its only six-lane wide. This slows down the vehicular speed drastically during peak hours, forcing the motorists to wait for several minutes to cross only 1.8 kilometers of distance.

A decision to construct another bridge was taken in 2012, which would be the third bridge to be constructed across Thane Creek channel with the existing bridge no. 2 saturating to traffic and bridge no. 1 closing operations due to its poor condition.

The first two-lane bridge over the Thane Creek bridge was built in 1973 to connect the city and Navi Mumbai and was named as Thane Creek Bridge-1.

The first two-lane bridge over the Thane Creek bridge was built in 1973 to connect the city and Navi Mumbai and was named as Thane Creek Bridge-1. The TCB-3 will be providing six more lanes to the existing bridge, making it a 12-lane bridge overall, which would mean much less traffic congestion at the entrance of Mumbai at Vashi and at the entrance of Navi Mumbai at Mankhurd.

While one of the dual bridges is being built besides the existing TCB-2, the other part of TCB-3 is being constructed between existing TCB-1 and TCB-2 in a gap of only 22 meters. Engineers have to be extra vigilant during construction in this part so at to ensure that they don’t touch or disturb the foundation of the existing bridge structure.

CONSTRUCTION CHALLENGES BEFORE TCB-3

Apart from the requisite engineering works over the water, the construction of the TCB-3 has several limitations thanks to the space constraints, existence of the old bridge, shallow water and tidal movements.

The most challenging task for the team is to move the heavy machinery on the shallow water and ensure it doesn’t disturb the structure of old bridges at any cost during the construction activity when the vehicular traffic is on round-the-clock.

Site supervisors say construction over the open sea — be it shallow or deep water — may be termed easier but construction over shallow water with a space constraint narrows down the scope of using several machineries, equipment and engineering methods, making it difficult and complex in nature.

While one part of the bridge has the advantage of one side being open, there is continuous vehicular traffic on its other side.

The most difficult is the second part of the bridge, which is being built between the two bridges (TCB-2 and TCB-1), leaving a gap of only 22 meters for construction activity between the two bridges.

It is only within this 22-meter distance that all the construction activity such as boring, drilling in the sea bed, piling the pillars, moving heavy machinery and installing a 13-metre-wide deck or bridge over the pillars has to be carried out.

After the finished structure, the gap on both sides of the new bridge with old bridges around remains only 2 metres.

“The scope of using heavy machinery and moving it freely and with a normal speed is almost impossible as there is no space. This slows down the pace of construction work as even a small mistake in the movement of the machineries can result in risking the existing functional bridge structures, which can turn out to be disastrous. The space constraints limit the use of modern technique or machineries and we have to use the machineries and manpower considering the condition of the site,” said an engineer working on the site. The engineer said if they had to build the same structure in the open sea, a different method, machineries and material could have been used which would have saved a lot of time and money.

He further adds that apart from the space constraint, the shallow water makes the work more difficult owing to the tidal waves, making them completely dependent on the tides — every activity takes place based on the high- and low-tide schedule.

The current of water during low tide is so strong that it moves a large part of clay completely and a little movement of machinery, the tug boats or jack barges can result in a mishap.

The supervisors at the site said to ensure that all the construction activity takes place considering the tidal schedule and its impact, a special marine team has been deployed at the site which includes marine experts and divers who monitor the water and the tides and accordingly, all the movement or construction activity over the sea is planned.

PLANING AND EXECUTION

Site engineers said the construction method, design and the machineries to be used for the construction were all planned in advance considering the issues and factors on the site where there is no scope of free movement.

The TCB-2 was built using a well foundation method wherein a dam like-structure was built to lay foundation or pillars.

The TCB-2 was built using a well foundation method wherein a dam like-structure was built to lay foundation or pillars.Owing to the existing structures, movement on the marine site and existence of mangroves and fishing activity, over a dozen mandatory permissions from different agencies like environment and maritime boards have to be taken.

Explaining the issues, the site engineers said that as per Maharashtra Maritime board’s regulations, the new bridge has to give a space for navigational purpose to the ships traversing under the bridge besides taking care of the underground utilities. Hence the third creek bridge’s design, height, location of the foundation and its size must be identical and in the same alignment to the older bridges’ construction.

DIFFERENCE BETWEEN OLD AND NEW BRIDGE

Even as the new bridge would be identical in size, design and alignment with the old bridges, the method and technique used for the construction is different.

The TCB-2 was built using a well foundation method wherein a dam like-structure was built to lay foundation or pillars.

On the TCB-3, however, the pile foundation is being used wherein a boring machine drills into the sea bed and then penetrates iron pipe into it. Once the iron shallow pipe is drilled, a reinforcement such as steel and concrete is poured. Once this is done, a substructure is built over which the superstructure, the actual bridge platform, is built.

In case of the TCB-3, a particular type of superstructure is being built using a method which is suitable to a site which has space constraints due to the existing structure and the shallow water. “There are two types of structures that we can have on the shallow water. One is precast segment wherein the concrete structure is cast in a shape in the yards and then brought at the site to install. However, due to the space constraints, it’s not possible on TCB-3 and hence, we are using form structure, which is similar to how house slabs are constructed. We are using a machine which keeps constructing the spans on the spot and concreting is done. This method is being adapted considering the current site condition and the structure which has been planned owing to the existing structure,” said an engineer.

MARINE EXPERTS AND OPERATORS TAKE CHARGE

A team of marine experts and divers, comprising 24 people, has been appointed at the site to look after the existing structure, its safety and stability, and movement of the marine machineries and barges.

This is the team which pulls the string at the site and decides the timetable there every day. The marine supervisors at the site said as the work has to be carried out in shallow water, the tidal movement affects it and hence, depending upon the tides’ schedule, heavy machineries and other activities have to be carried out during a particular timing.

Every team member has a schedule of the tidal movement of each day and accordingly, the movement and different steps of construction activities are planned and executed.

“There is a very high current in the water owing to the tides and hence, we carry out the movement on select water-level location. We have to consider the water level at different locations as there are structures above and adjacent to the upcoming structure. During high tide, water level increases… the machine cannot be moved or even kept in the marine at this time,” said the marine senior supervisor at the site. “We get high tide and low tide at a period of six hours each. There is a period of one or two hours between the tidal movement and this is when we have to carry out all the activity. For example, for the jack-up barge, we get only two hours during which we have to carry out all the movement. As soon as these two hours gets over, we have to wrap up the work otherwise, due to the current, the barge will touch either side of the existing bridge… It is a very sensitive site,” he said.

Another supervisor pointed out at the presence of a railway bridge on one side which has a 4500-volt electric power line. “This is very risky and needs to be considered while doing movement during tides. Any mistake in the timing of the movement and position during tides can result in a major disaster and casualties,” the supervisor added.

In all, the marine supervisors said, they get only four hours every day to execute all the movement of barges and carry out other work. A delay of even a few minutes can result in a major issue and create a possibility of a mishap.

PARKING AN ISSUE IN SEA TOO

There are over 25 marine equipments, including different types of barges and tug boats, being used on this site.

Another issue that the team faces working on the site is parking. The marine workers and supervisors say the barges, tug boats and machineries over it cannot be parked at random location in the sea as there is also movement of boats on the water. Besides, during rainy season, a different strategy has to be used and there is almost no scope for activity.

A supervisor said rainy season sees high-pressure wind which can move barges several meters away, rendering them out of control. “Last monsoon, one of our barges with workers inside got caught in the winds and current of water. The current and the wind were so strong that the barge was uncontrollable and it was taking us towards the railway bridge over which local trains run and where there is also a high-voltage power line. It was only due to god’s grace that the wind stopped for a few minutes. Otherwise, something unimaginable could have happened,” said the marine worker.

CURRENT STATUS

Kicked off in 2020, 15 per cent of work has been completed on the bridge so far. The work was slowed down owing to the Covid-19 pandemic. Around 50 per cent piling or foundation work has been completed as of yet. On November 24, 2017, the state government had given administrative approval of Rs 1775.58 crore for the project. The grace period for recovery of this project is from 01.10.2027 to 29.09.2036. For the construction of this project, contractor L&T was selected and work of Rs 559 crore was issued in October 2020.

The deadline for completion of the project was 36 months from the date of handing out contract followed by a defective payment period of 48 months after completion of work. Officials are hoping that the project will get completed by next year. “Around 15 per cent of work on the Thane Creek Bridge-3 is completed and it is expected to be readied before the end of 2023. The TCB-3 will ease out the traffic issue on the stretch,” said Anil Kumar Gaikwad, Joint Managing Director of MSRDC.

- The Indian Express website has been rated GREEN for its credibility and trustworthiness by Newsguard, a global service that rates news sources for their journalistic standards.