:quality(80)/images.vogel.de/vogelonline/bdb/1839900/1839933/original.jpg)

Case Study Sizing of a Suction Pulsation Dampener with Suction Pressure Below Atmospheric

The suction pulsation dampener is necessary in order to: Maintain flow velocity in the suction pipe constant and avoid cavitation, and achieve a smooth suction pressure.

Related Companies

Circuit Details:

Pump: Peristaltic pump with a flow of 1.057 gallons/h and 25 spm.

Piping: 2” suction pipe.

The pump suctions grey water from an underground sewage pit. A filter was installed in the sewage pit in order to re-use the water for a golf course.

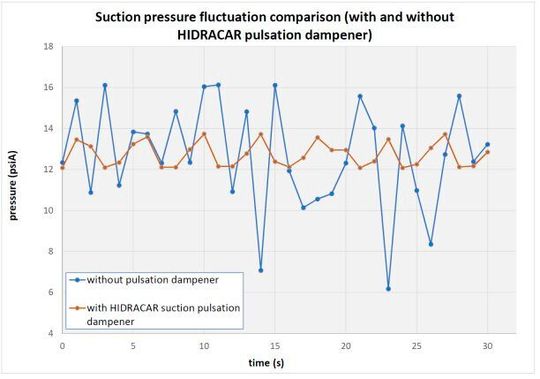

The end user installed an electronic sensor in order to detect the loss of head across the filter. It was established that when the suction pressure falls below +10psiA, the filter ought to be cleaned. The pressure oscillated from +16psiA to +6,5psiA without the pulsation dampener and with the filter in clean conditions. Therefore, the electronic sensor was not able to detect the increase of loss head across the filter due to the exiting pressure oscillations.

The client requested Hidracar to determine the dampener optimum size and design to reduce the pulsations till a reaching oscillation amplitude of 2psiA.

Problem Resolution

Hidracar proposed the installation of the Bladder Pulsation Dampener with 2 connection ports. The dampener thread connection and transversal hole had the same diameter of the pipe (2”).

The efficiency of the Suction Pulsation Dampener is guaranteed thanks to its special design and in-line disposition described below:

- The two ports of the Dampener are aligned with the suction piping.

- The diameter of the Dampener's transversal threaded hole is the same as the suction piping.

- The bladder is in direct contact with the vein flow.

- The hole passage inside the dampener has a section four times larger than standard.

Suction Pulsation Dampener Sizing

The dampener size is obtained in the same manner as for the pump discharge sizing. It was considered an admissible pressure oscillation (customer requirement): P2(max)-P1(min)= 2 psiA

The dampener volume obtained was Vo= 115,5 inch3

Hidracar immediately selected the larger volume: U030 with Vo= 159 inch3

Determination OF V3 (bladder gas volume in delivery conditions)

V1 = V2 + δV (volume fluctuation); P3= Atmospheric pressure

Hidracar delivered the pulsation dampener with the bladder compressed at V3

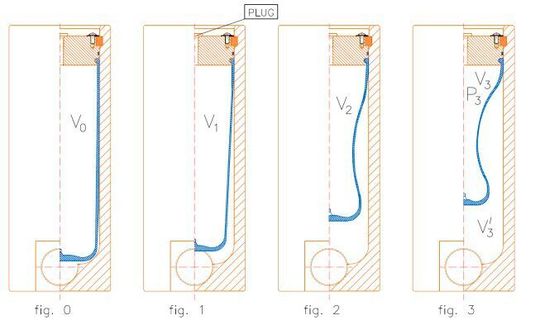

In the Fig.0, the bladder is occupying all the volume inside its body. The total volume Vo= 159 inch3.

In the Fig.1, the bladder is slightly elongated and the gas volume in is V1. P1= +12psiA.

In the Fig.2, the bladder is slightly compressed and the gas volume is V2. P2= +14psiA.

In working conditions, the gas volume is fluctuating between Fig.1 and Fig.2. δV= V1-V2 = C /5 = 16,5 inch3. (for a peristaltic pump)

In Fig.3, the gas volume is V3 which is the volume that has to be pre-set in delivery conditions at atmospheric pressure (14,7psiA).

From the equality provided by the Boyle Mariotte formula:

Po x Vo = P1 x V1 = P2 x V2 = P3 x V3

Therefore, we can deduce:

V1 = P2 x δV / (P2-P1) = 115,5 inch3

and

V3 = P1 x V1 / P3 = 110 inch3

Pressure Oscillations Results After the Installation of the Suction Pulsation Dampener

The blue line shows the variability of pressure without the Hidracar Suction Pulsation Dampener.

In the red line, once the Suction Pulsation Dampener was installed, the pressure variability was significantly reduced between +12psiA and +14psiA; and the sensor was successfully calibrated at +10psiA.

(ID:47452850)

:quality(80)/images.vogel.de/vogelonline/bdb/1838700/1838796/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1836600/1836693/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1836500/1836532/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1839900/1839948/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1839500/1839518/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1838800/1838816/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1838700/1838738/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1838300/1838395/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1836400/1836498/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1827600/1827658/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1830800/1830869/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1838300/1838310/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1838000/1838049/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1835200/1835264/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1832700/1832755/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1839600/1839675/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1838400/1838431/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1838500/1838559/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1837700/1837708/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1839800/1839874/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1839800/1839822/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1839600/1839639/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1807900/1807985/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1797900/1797927/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1797600/1797603/original.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/67000/67026/65.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1690500/1690519/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1722400/1722449/original.jpg)