- News

- City News

- ahmedabad News

- Gujarat: Kutch cylinder units restart as liquid oxygen supply resumes

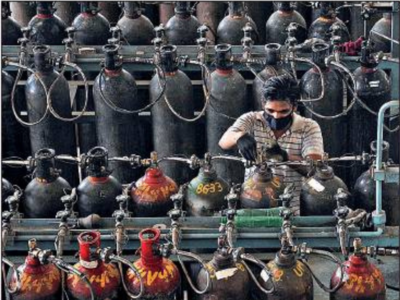

Gujarat: Kutch cylinder units restart as liquid oxygen supply resumes

The local authorities are also monitoring the supply of liquid oxygen being made available to these units, added sources.

AHMEDABAD: Oxygen cylinder manufacturing plants in Kutch district have resumed operations with liquid oxygen being made available to them. The oxygen cylinder makers had to temporarily shut production for the want of liquid oxygen amid the unprecedented surge in Covid-19 cases and the consequent spike in the demand for the lifesaving gas from hospitals.

Liquid oxygen is a raw material used in the process of making seamless cylinders that store medical-grade oxygen. As an input, liquid oxygen is used to generate high temperature for making bottoms and necks of empty cylinders.

“Both the units in Kandla SEZ have resumed operations and they are making oxygen cylinders,” confirmed Dr Amiya Chandra, zonal development commissioner, Kandla Special Economic Zone (KASEZ).

KASEZ houses the plants of two leading seamless cylinder makers, Everest Kanto Cylinder and Rama Cylinders. There is one more plant operated by Rama Cylinders at Bhimsar in Anjar. “This unit is also functional now,” said a source privy to the information.

These units could resume operations with liquid oxygen being made available through different resources, including imports, arrangement from other states, and procurement from local suppliers within Gujarat, said sources aware of the matter.

“The government provided liquid oxygen imported from Saudi Arabia, while our local supplier also resumed the supply. Hence, we could restart producing oxygen cylinders,” said one of top cylinder manufacturers in the Kandla SEZ.

A consignment of liquid oxygen was also arranged from another state for one of the units in Kutch, said sources aware of the matter.

The local authorities are also monitoring the supply of liquid oxygen being made available to these units, added sources.

Oxygen cylinder manufacturers had been forced to stop production at their plants for a few days as they were unable to procure liquid oxygen for running their plants. These plants could not be supplied the required liquid oxygen as local suppliers were providing all their supplies to hospitals to save human lives amid the fierce second wave.

Liquid oxygen is a raw material used in the process of making seamless cylinders that store medical-grade oxygen. As an input, liquid oxygen is used to generate high temperature for making bottoms and necks of empty cylinders.

“Both the units in Kandla SEZ have resumed operations and they are making oxygen cylinders,” confirmed Dr Amiya Chandra, zonal development commissioner, Kandla Special Economic Zone (KASEZ).

KASEZ houses the plants of two leading seamless cylinder makers, Everest Kanto Cylinder and Rama Cylinders. There is one more plant operated by Rama Cylinders at Bhimsar in Anjar. “This unit is also functional now,” said a source privy to the information.

These units could resume operations with liquid oxygen being made available through different resources, including imports, arrangement from other states, and procurement from local suppliers within Gujarat, said sources aware of the matter.

“The government provided liquid oxygen imported from Saudi Arabia, while our local supplier also resumed the supply. Hence, we could restart producing oxygen cylinders,” said one of top cylinder manufacturers in the Kandla SEZ.

A consignment of liquid oxygen was also arranged from another state for one of the units in Kutch, said sources aware of the matter.

The local authorities are also monitoring the supply of liquid oxygen being made available to these units, added sources.

Oxygen cylinder manufacturers had been forced to stop production at their plants for a few days as they were unable to procure liquid oxygen for running their plants. These plants could not be supplied the required liquid oxygen as local suppliers were providing all their supplies to hospitals to save human lives amid the fierce second wave.

FacebookTwitterLinkedinEMail

end of article

Trending Topics

Top Stories Right Now

- indiaAt Rs 700-Rs 1,500, price of Covid vaccine in India’s private sector among costl...

- indiaCovid: Growth in cases slows but death rate crosses 1%

- indiaCovid live: Karnataka biweekly cases highest after Maharashtra

- indiaAssam: Sarma’s report card of 5 years may have landed him top job

- indiaCEC: Never thought of deferring assembly polls due to Covid surge

Quick Links

Delhi Air PollutionDelhi TemperatureChennai WeatherBangalore TemperatureCovid vaccination centres in DelhiCoronavirus in DelhiRTPCR test in GurgaonHyderabad RainPollution level in BangaloreDelhi SmogDelhi TemperatureNoida AQIGurgaon AQI todayFire in MumbaiMumbai RainsCovid 19 RT PCR Test in NoidaDelhi AQI todaySrinagar encounter