:quality(80)/images.vogel.de/vogelonline/bdb/1824700/1824702/original.jpg)

Germany: Position Paper Material Recycling in a Circular Economy for Plastics

Creacycle, EPC Engineering & Technologies and Lömi have developed a position paper which is a critical assessment on the topic ‘Material Recycling in a Circular Economy for Plastics’. Together, the companies propose an EU directive specifically for plastic waste.

Related Companies

Grevenbroich/Germany – In order to raise the discussion on the topic of Circular Economy for plastics to a fact-based level, Creacycle, EPC Engineering & Technologies and Lömi have developed a position paper that addresses all parties involved in this topic. They call for the improvement of the current terminology of the relevant waste directives, including the incorporation of the latest available technologies for plastics recycling, such as solvent-based purification/dissolution. They propose an EU directive specifically for plastic waste, allowing for a recovery hierarchy based on physical and chemical processes.

In addition, the paper addresses the need for improved sorting capabilities for material recycling and a regulatory framework that ensures end-of-life costs are considered. Finally, the authors call for the recognition and inclusion of solvent-based purification/dissolution as material recycling for the purpose of calculating recycling quotas. The position paper is available for download here.

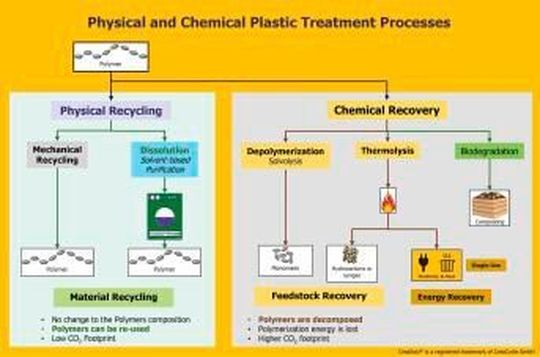

As a basis for future developments, the authors call for a more precise definition of the term ‘recycling.’ This must be in accordance with the findings of physics and chemistry, should follow the concept of the waste hierarchy (reduce - reuse - recycle), be based on the value chain for plastics (chemical element - intermediate - monomer - polymer - plastic) and define material recycling (polymer to polymer) as preparation for reuse of the polymer component.

Gerald Altnau, Managing Director of Creacycle, comments: "The EU has so far lacked a recovery hierarchy. In addition, the current waste directives for polymer-based waste are not differentiated enough, and they do not take into account conditions for repeated reuse of one and the same material, i.e. material recycling of polymers. Recycling is used as a generic term that defines reuse and downcycling (depolymerization) as equivalent. While this allows high recycling rates to be achieved, it creates conflicts for plastics because reuse and recycling occupy two different positions in the waste hierarchy."

In this context, the authors point to what they see as the underutilized potential of solvent-based purification. They call for this physical process of material recycling to be included in the waste directives, as it falls between mechanical and chemical recycling processes that have been discussed as the sole alternatives to date, and can enable the reuse of polymers from plastic waste that today must be incinerated.

As an example, they cite the Creasolv Process, which among other things offers a new alternative to incineration for the reprocessing of expanded polystyrene (EPS) contaminated with harmful substances. This advanced separation or sorting technology was developed by Creacycle and the Fraunhofer Institute IVV for Packaging and Process Engineering. EPC Engineering & Technologies and Lömi were involved in process development, design and construction of pilot plants.

Currently, together with Polystyreneloop, they are building a Creasolv Process demonstration plant for the recycling of flame retarded polystyrene insulation foam boards from the construction sector with a capacity of 3,300 t/year. Polystyreneloop has more than 70 members from the polystyrene foam value chain and was formed to develop a recycling solution capable of separating polystyrene from the flame retardant HBCD (hexabromocyclododecane), now classified as a persistent organic pollutant (POP).

(ID:47371055)

:quality(80)/images.vogel.de/vogelonline/bdb/1823900/1823911/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1822900/1822982/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1821300/1821348/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1823700/1823763/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1823100/1823191/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1822400/1822474/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1822400/1822478/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824100/1824152/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1823600/1823667/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1819600/1819615/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1816000/1816056/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824700/1824750/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824300/1824381/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824100/1824141/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1820800/1820843/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824100/1824149/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824100/1824146/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1814700/1814760/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1790500/1790528/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824800/1824807/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824600/1824690/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1824300/1824395/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1807900/1807985/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1797900/1797927/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1797600/1797603/original.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/101800/101879/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/95500/95538/65.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1815900/1815976/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/1733500/1733597/original.jpg)