Epson Atmix Corporation, which is an Epson Group company, is “a leader in the manufacture” of superfine alloy powders, has started up operations on a new production line at its Kita-Inter Plant in Japan. The new production line uses a water-atomisation process to produce superfine alloy powders.

Epson says its new line will enable Epson Atmix to increase its total production capacity to about 15,000 tons per year, which is about 1.5 times its current production capacity, by 2025.

Epson Atmix says its “water-atomised superfine alloy powders are classified into two main types depending on what they are made from and how they will be used. The two types are magnetic powders and sintered powders for metal injection moulding (MIM)”.

Note: Metal injection moulding is a metalworking process that combines the features of injection moulding and powder metallurgy. MIM is used to process superfine alloy powder into parts of various shapes that have high accuracy, density, and strength.

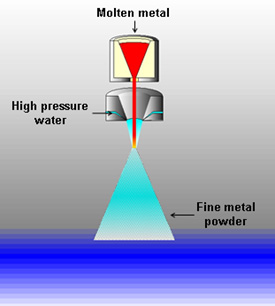

The company says its has “added its own technology to a water atomisation process in which high-pressure jets of water are impinged on a stream of molten metal from a high-frequency induction furnace to cause the metal to burst into a mist that is then rapidly cooled”.

Note: Water atomisation is a process for manufacturing superfine alloy powders in which a stream of molten metal from a high-frequency induction furnace is hit by jets of water, creating powder particles that are then rapidly cooled.

Epson Atmix continues stating: “This process has helped the company earn an outstanding reputation in the market by enabling it to produce micron-order granules and provide superfine alloy powders that are consistent and have a uniform composition and characteristics”.

So, why are magnetic powders important?

The company tells us all that “magnetic powders have excellent magnetic properties and serve as raw materials for electronic components such as inductors, choke coils, and reactors required to control the voltage of high-performance mobile devices such as smartphones and laptop computers.

“The market for these powders is expected to expand further in the future owing particularly to an increase in the use of electrical components in automobiles and an increase in the number of inductors installed in hybrid and EV vehicles. Epson Atmix's magnetic powders control energy loss thanks to the company's technology for producing micro-granules.

“These powders also contribute significantly to reducing the power consumption and size of electrically controlled components and to the support of high frequencies and large currents.

“Meanwhile, sintered powders are used in MIM parts that have complex shapes and that require high dimensional accuracy and high strength, such as parts for medical equipment, automobile engine applications, electronic equipment, and office-automation equipment. In addition, demand is expected to grow in the industrial field as metal 3D printers become increasingly common.

“Epson Atmix's extensive line-up of sintered powders includes stainless steel and low alloy steel. The grain size can be adjusted according to the application to increase sintered part density and strength. The growth of the medical, automotive, and 3D printer markets, among others, is expected to contribute to stable demand going forward”.

Note: Ordinary alloys have a crystal structure in which atoms are regularly arranged. Amorphous alloys, on the other hand, are made up of atoms that have an irregular arrangement, so although they are solid, they are similar to liquids in that they have densely packed atoms arranged in an irregular structure. Made up of granules with diameters ranging from several dozen to several hundreds of microns, amorphous alloy powder is lightweight and has excellent energy conductivity and strength.

The company adds: “Superfine alloy powders are used in the manufacture of parts used in high-performance mobile devices such as smartphones and tablet PCs, as well as in automobiles and medical devices. The market for these powders has been showing annual growth, a trend that is expected to continue”.

Epson Atmix concludes by stating it will “respond to this strong demand by increasing the capacity of fine alloy powders”.