You only need to drive a Jaguar I-Pace a few hundred metres down a city street to know that Britain’s first electric luxury car continues to generate huge interest. Onlookers’ eyes sweep approvingly over its rising and falling flanks as you glide along. Stop anywhere and you’ll soon be part of an enthusiastic “what’s it like” conversation that at times can build a small crowd.

It’s clear the I-Pace has filled enough news pages and TV screens to command near-instant recognition from those with the vaguest interest in cars. Can’t afford one, most people say, but I’m glad they’re doing it. Which makes the I-Pace much more important than simply being the early adopter’s luxury car of choice. It’s helping sell people on the enormous changes coming to every corner of the car market.

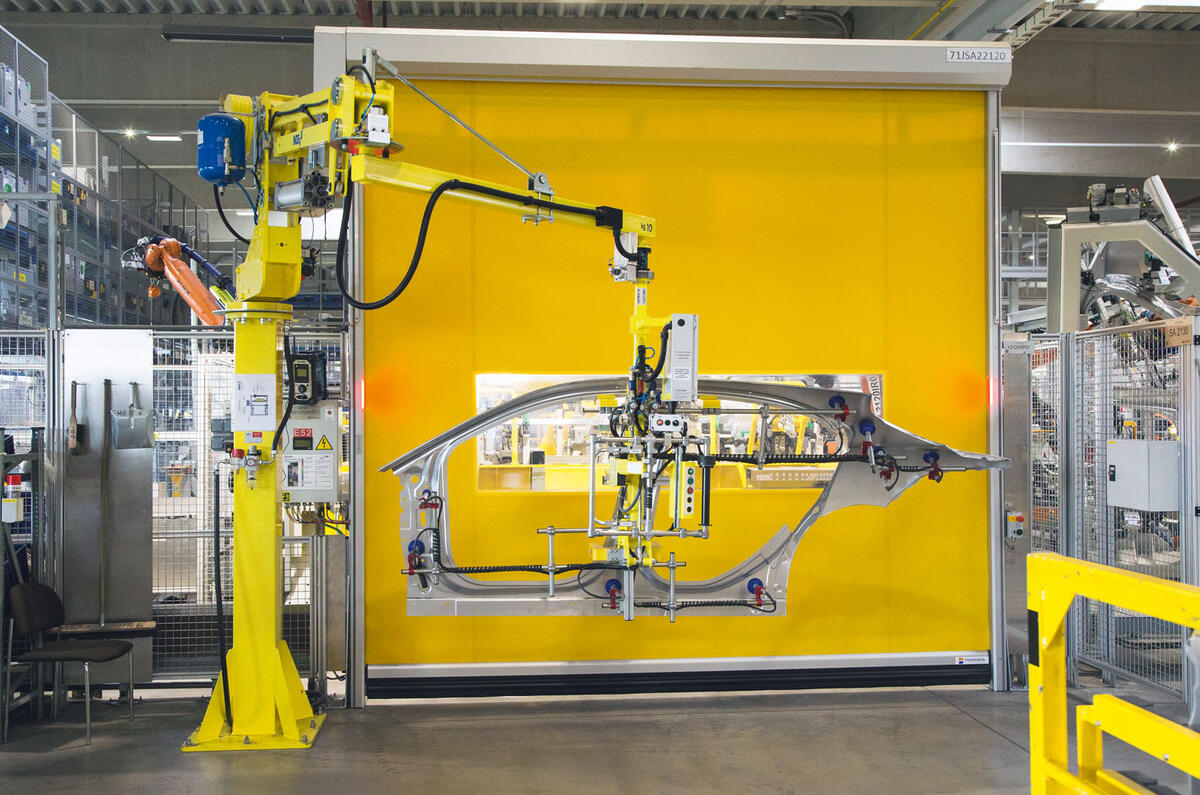

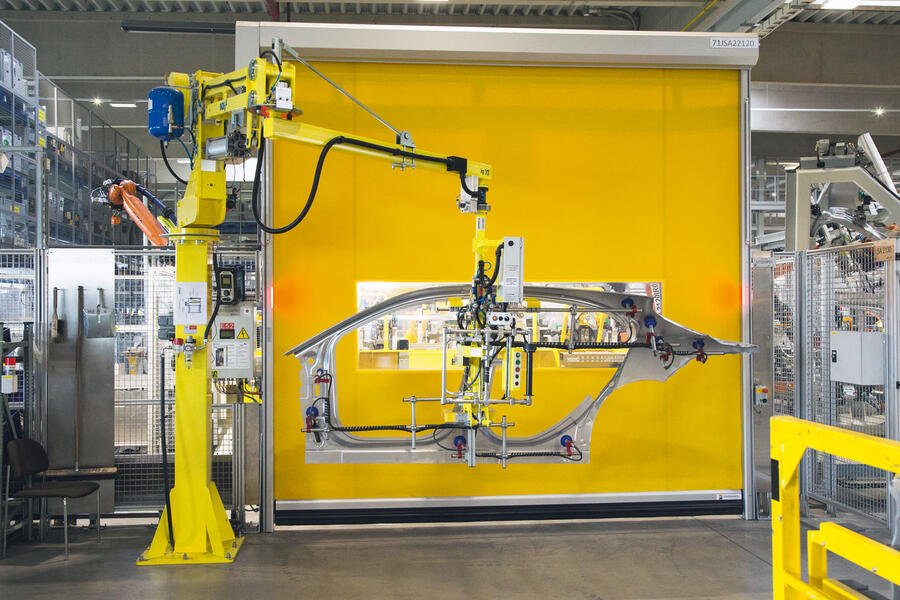

What I-Pace audiences rarely know is how and where the car is made. People are always surprised to learn it comes from a vast and venerable factory in Graz, Austria, operated by a unique company, Magna Steyr, whose business model is to build unusual cars for prestige clients that mostly demand great production flexibility as well. Some people are pleased to hear the new Jag has been devolved to Europe, given Jaguar Land Rover’s current difficulties and the lingering uncertainties of Brexit. Others are disappointed because Jaguars have always been so British. Still, the system works. Nowadays, there are two Graz Jaguars – the I-Pace sharing its flexible final assembly line with the entirely different E-Pace compact SUV, now Jaguar’s best-selling model.

Why choose Magna? Because when these models were nearing launch, JLR production was already at capacity. Graz was ideal because it had successfully built dozens of different brands and models over the years, always at impressive quality. The 90-year-old business was started late in the horse-drawn age by a Slovenian immigrant called Johann Puch (the sign off the autobahn still says ‘Puchwerk’) who made bicycles, motorbikes and light cars until he joined an expanded Steyr-Daimler-Puch company in the 1930s.

Join the debate

LJames

Cant see why anyone would buy

Cant see why anyone would buy a Tesla instead. Jaguar holds 1st place in electric cars (for the moment)

wheelman

Jameson -

Jameson -

Are you kidding me? A Tesla - of any model - will go faster, longer and can be easily charged up and down the country. Ignore what you read in Autocar; they provide real world numbers for Tesla reviews and then whatever the PR dept at JLR says for the iPace. The iPace certainly handles well and enjoys a European standard cabin, but the battery results come from the same guy who clearly came up with the defeat device for Volkswagen. Its never mentioned in the pages of Autocar, but an 85Kwh battery in the iPace is less efficient than 85Kwh in a Tesla - vastly better software. And best of luck charging it after the more likely 200 miles... you'll need a 5-course dinner and a few coffees before it even takes on 100 miles of extra charge - all at 35p per KWh - thats when the charger works or is even available.

John Savill

How far will they go?

A certain monthly magazine publishes it's own real world EV ranges

Tesla Model S 75D 204 miles

Tesla Model X 100D 233 miles

Jaguar i-Pace 253 miles

All beaten by the Hyundai Kona electric 64kwH 259 miles.

The advantage of Tesla in chargers will be eroded as BP for example rapid install chargers in their 1200 stations

jason_recliner

Autocar wrote:

Those people are called Austrians.

LJames

Funny how they named the E

Funny how they named the E-pace. If it had come later, the I-pace would have probably got its name.

LP in Brighton

Profitability

Surely it doesn't make sense for Jaguar to built potentialy its biggest selling model abroad via a third party manufacturer? Building any model in low volume is expensive, especially when you're employing someone else to do it for you. And in the current climate with JLR's UK factories lying substantially idle, it's sheer lunacy.

concinnity

Lunacy?

It's good to see that JLR are protecting their European sales from the lunacy of Brexit by making some of their cars there. They'll be easier to export from there too, after a Brexit, because the EU has existing trade agreements with most other countries, and the UK doesn't.

scotty5

Crystal balls

See my reply below - if you actually read Steve's article you'll have noted the decision to build the car in Graz was taken BEFORE the Brexit vote. The referedum took place June 2016, according to Steve's article, JLR first spoke to the Austrians 5 years ago - that'd make it 2014.

Are you suggesting some of that £3.4billion was spent on clairvoyants?

scrap

scotty5]</p><p>[quote

Get a grip mate. Brexit is killing UK manufacturing and denying it is like denying climate change. UK government has spent far too much time pandering to fools like you.

GODFATHER

scrap]</p><p>[quote=scotty5

Wrong - the diesel gate has done triple the damage that Brexit has done. Regulations by the EU/UK governments forced us into buying diesels only to be proven wrong. Now they have been targeting diesel at short notice leaving the heavily diesel reliant maker such as JLR, Nissan to catch up. Notice how Honda and Toyota who were more petrol reliant, ain’t struggling.

Pages

Add your comment