Twenty years ago, DaimlerChrysler, as the two merged companies were called then, launched the A-Class-based Necar 4, the first production-ready fuel cell vehicle capable of being driven on public roads. The plan was for the first commercial version, dubbed, ‘Necar X’ to be launched on public sale in 2004.

By that time, DaimlerChrysler said it would have spent over £1.1 billion on fuel cell vehicle development: it was that big and looked that certain. The board member responsible for R&D, Klaus-Dieter Vöhringer, said back then: “From 2004 to 2010, the population of fuel cell vehicles has to increase very fast otherwise the [refuelling] infrastructure will not grow.” He was dead right in one sense: it didn’t grow and fuel cell cars haven’t taken to the roads in large numbers. Yet.

Some would say hydrogen fuel cells are the holy grail of sustainable propulsion because they emit nothing except water and heat from the tailpipe. So long as the hydrogen fuel they consume is produced sustainably, it’s an environmental free lunch with refuelling pretty much as easy and fast as it is with petrol or diesel. In common with a battery, a fuel cell ‘stack’ consists of hundreds of individual cells producing a little over one volt each.

The favoured technology for cars and transport is the polymer exchange membrane (PEM) fuel cell. A fine polymer membrane sandwiched between a platinum cathode and anode and two flow plates in a kind of double-decker sandwich make up each cell. Hydrogen travels through the flow plates on the anode side while air is pumped through the cathode side as a source of oxygen. Hydrogen protons are attracted through the membrane to the oxygen, making water, leaving the hydrogen electrons behind, forming a current in an external circuit.

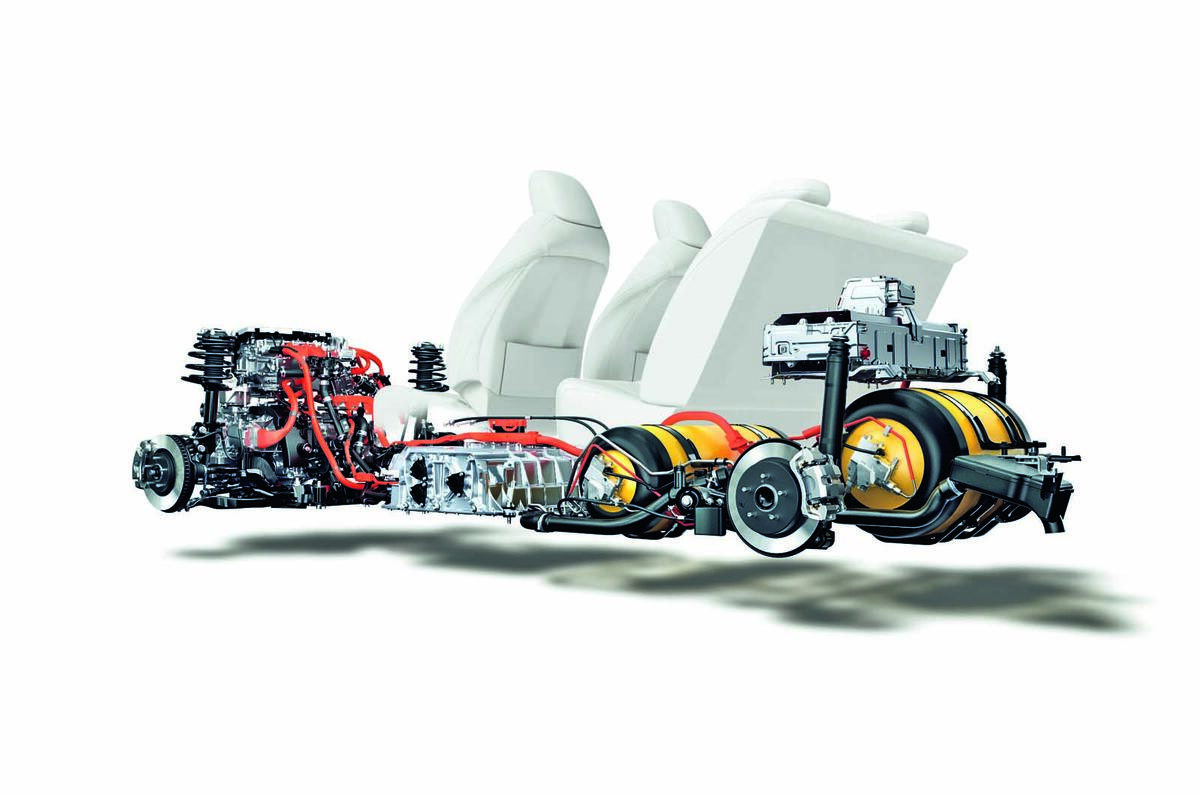

There have been lots of technical hurdles to overcome – including scavenging residual water from inside the cells, which would freeze at low temperatures, starting the stack in sub-zero temperatures, economic manufacture and robustness – but today fuel cell systems are advanced, if still pricey. An entire fuel cell system consists of a stack, a carbonfibre tank capable of storing hydrogen at 750 bar and a small lithium ion battery to deliver both the fast surge of power needed for acceleration and to store energy from regenerative braking. Tough hydrogen tanks split and release hydrogen rather than exploding if damaged and, in that sense, the world’s most plentiful element is safer than petrol. The rest of the powertrain is like that of any other electric car, with an electric motor and power control module to manage it all.

Add your comment