SABANG: The commonplace ‘madur’ (mats), swept off the floor in Bengali households by trendier rugs and luxurious carpets, seems to have hit the jackpot in foreign shores.

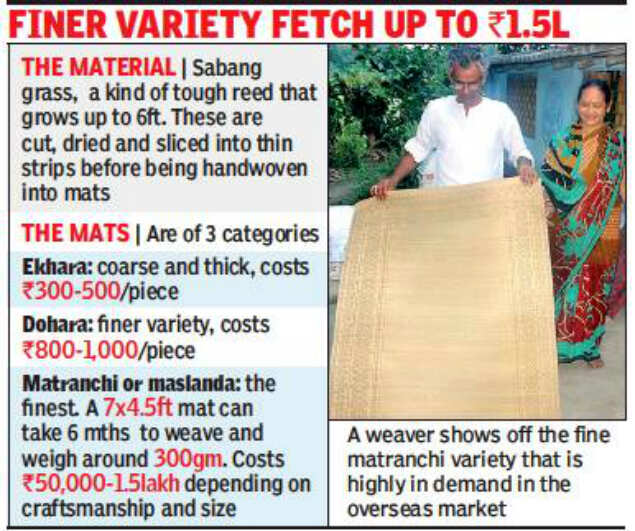

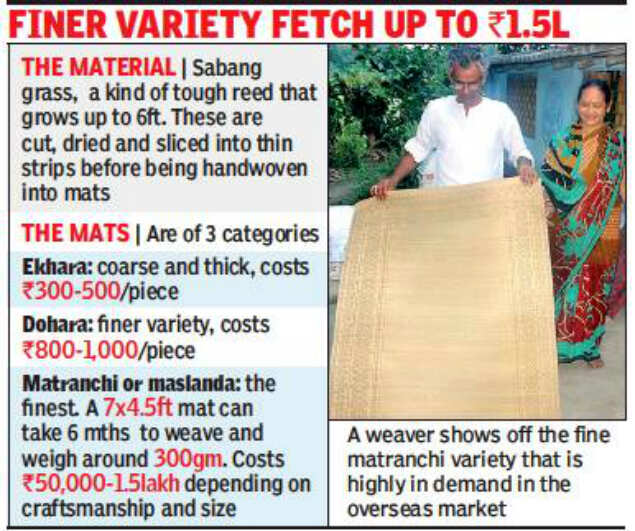

Made of a natural reed known as ‘Sabang grass’, these handwoven traditional mats from Midnapore are flying off the shelves in Europe, where they are being used as wall hangings and bed throws. Particularly in demand is the finer matranchi or masland variety — the grass equivalent of mulmul — which fetches anything between Rs 50,000 and Rs 1.5 lakh a piece.

The sudden spotlight is primarily a result of government initiative that allows craftsmen to showcase their ware at art and handicraft festivals abroad. The journey from anonymity to stardom began six years ago with the showcasing of national award winning craftsman Alak Jana’s masland variety of mats in the Harare Arts Festival in 2013. They were an instant hit.

This prompted the state directorate of textiles and the state Khadi Board to launch a project to revive a craft that was once an integral part of Bengal’s lifestyle. An NGO, Banglanatak.com, was roped in to oversee the project in Sabang, Pingla and Narayangarh blocks of Midnapore, where weaving madur has been a way of life for centuries. Biswa Bangla took care of the branding and a GI tag followed in 2018. Besides reviving a dying art, the initiative brought close to 4,500 weavers out of abject penury, hiking their daily income from as little as Rs 100 to Rs 3,000 for the more skilled ones. Today, weavers from Sabang jet across the globe to showcase their wares at festivals in Germany, Hungary, Norway, Sweden, Denmark, London, France, China, South Korea and Oman to name a few.

“What is heartening is each weaver has been able to convert every single foreign festival opportunity into steady business,” says Amitabha Bhattacharya, head of Banglanatak.com.

Ashok Jana, for example, has 450 tote bags to complete for a customer in Japan. Thereafter, he has another order of 1,000 handbags lined up. “There’s no dearth of orders,” he says, “You’ll find most of us busy with overseas orders at all times. When we are free, we complete our orders for Biswa Bangla stores.”

Gouri Jana, busy giving finishing touches to wares she will be taking with her to the Hungary Heritage Festival in August, is wiser after participation in the festivals of Kyrghystan and Sweden. “I will not only be taking the maslanda mat but also a lot of bags, hats and table mats,” she says.

Neighbour Mithu Rani Jana, who will be leaving for the Karlsruhe Festival in Germany next month, says no matter how much stuff she takes with her, stocks get exhausted in no time and she spends the rest of the festival days taking orders for more.

Ashoke, Gouri, Mithu and the others are provided logistic support by the Khadi Board. “We help with their travel, accommodation and negotiations, and once the weavers bring back their orders, we help them with the deliveries through trained marketing personnel,” says Biswajit Sarkar, planning officer of the Khadi Board.

Made of a natural reed known as ‘Sabang grass’, these handwoven traditional mats from Midnapore are flying off the shelves in Europe, where they are being used as wall hangings and bed throws. Particularly in demand is the finer matranchi or masland variety — the grass equivalent of mulmul — which fetches anything between Rs 50,000 and Rs 1.5 lakh a piece.

The sudden spotlight is primarily a result of government initiative that allows craftsmen to showcase their ware at art and handicraft festivals abroad. The journey from anonymity to stardom began six years ago with the showcasing of national award winning craftsman Alak Jana’s masland variety of mats in the Harare Arts Festival in 2013. They were an instant hit.

This prompted the state directorate of textiles and the state Khadi Board to launch a project to revive a craft that was once an integral part of Bengal’s lifestyle. An NGO, Banglanatak.com, was roped in to oversee the project in Sabang, Pingla and Narayangarh blocks of Midnapore, where weaving madur has been a way of life for centuries. Biswa Bangla took care of the branding and a GI tag followed in 2018. Besides reviving a dying art, the initiative brought close to 4,500 weavers out of abject penury, hiking their daily income from as little as Rs 100 to Rs 3,000 for the more skilled ones. Today, weavers from Sabang jet across the globe to showcase their wares at festivals in Germany, Hungary, Norway, Sweden, Denmark, London, France, China, South Korea and Oman to name a few.

“What is heartening is each weaver has been able to convert every single foreign festival opportunity into steady business,” says Amitabha Bhattacharya, head of Banglanatak.com.

Ashok Jana, for example, has 450 tote bags to complete for a customer in Japan. Thereafter, he has another order of 1,000 handbags lined up. “There’s no dearth of orders,” he says, “You’ll find most of us busy with overseas orders at all times. When we are free, we complete our orders for Biswa Bangla stores.”

Gouri Jana, busy giving finishing touches to wares she will be taking with her to the Hungary Heritage Festival in August, is wiser after participation in the festivals of Kyrghystan and Sweden. “I will not only be taking the maslanda mat but also a lot of bags, hats and table mats,” she says.

Neighbour Mithu Rani Jana, who will be leaving for the Karlsruhe Festival in Germany next month, says no matter how much stuff she takes with her, stocks get exhausted in no time and she spends the rest of the festival days taking orders for more.

Ashoke, Gouri, Mithu and the others are provided logistic support by the Khadi Board. “We help with their travel, accommodation and negotiations, and once the weavers bring back their orders, we help them with the deliveries through trained marketing personnel,” says Biswajit Sarkar, planning officer of the Khadi Board.

World Cup 2019

Trending Topics

LATEST VIDEOS

More from TOI

Navbharat Times

Featured Today in Travel

Quick Links

Lok Sabha Election Schedule 2019Lok Sabha Election NewsDelhi Capitals teamMI team 2019Rajasthan Royals 2019RCB team 2019Maharashtra Lok Sabha ConstituenciesBJP Candidate ListBJP List 2019 TamilnaduShiv Sena List 2019AP BJP List 2019Mamata BanerjeeBJP List 2019 MaharashtraPriyanka GandhiBJP List 2019 KarnatakaAMMK Candidate List 2019BJP List 2019 WBLok Sabha Elections in Tamil NaduBSP List 2019 UPNews in TamilLok Sabha Poll 2019Satta Matka 2018PM ModiMahagathbandhanNagpur BJP Candidate ListChandrababu NaiduTamil Nadu ElectionsUrmila MatondkarNews in TeluguMadras High CourtTejashwi YadavArvind KejriwalTejasvi SuryaPawan KalyanArvind KejriwalYogi AdityanathJaya PradaSatta King 2019Srinagar encounter

Get the app